Overview

Although wireless is now commonplace, with homes, offices, coffee shops, hotels, and other establishments around the world offering easy access to the Internet via strategically placed Wi-Fi hotspots, wireless is still somewhat of a holy grail for industrial automation applications. The benefits of using wireless for industrial automation applications are certainly alluring enough:

• Cost: Wireless is cheaper than wired networks since less investment is required on cabling, installation, and maintenance.

• Mobility: Wireless is ideal for hard-to-wire applications, like the AGV (auto guided vehicle) applications used in warehouses.

• Scalability: Wireless makes it much easier to expand existing operations since you do not need to install additional cabling.

The downside of using wireless for industrial automation applications is that it is much harder to meet the stringent reliability requirements demanded by industrial automation. Whereas a brief, several second cessation of service for a routine office application might be viewed as a mere nuisance, for critical automation applications the same cessation could cause an unacceptable interruption in a factory’s operation.

This is why reliability is so important. Due to the fact that wireless is being deployed much more frequently than before, operators need to make sure that their network is reliable. Network failure can have a marked effect on both safety and productivity, resulting in big financial losses. In this paper, we discuss certain critical factors you must be aware of to ensure the reliability of your wireless network, and suggest solutions that are appropriate for mission-critical applications.

Critical factors and solutions

Implementing wireless communication in factory environments requires special considerations. Modern factories use lots of equipment, including robust, industrial-grade robot arms on the production line, a variety of sensors and actuators for automation, and even unmanned AGVs to increase efficiency. Since much of the equipment is made from industrial-strength metal that protects complex electronics, it’s no wonder that this kind of environment creates a number of obstacles to implementing seamless wireless communications.

In particular, operators need to learn how to deal with multipath effects, which can generate interference that causes information distortion or packet loss. In addition, electrical disturbances such as ground loops need to be handled properly to avoid interruptions in wireless transmissions. And finally, when mobility is required for greater efficiency, providing a seamless roaming mechanism is essential to ensure that the moving objects can reliably receive and transmit data.

Multipath effects

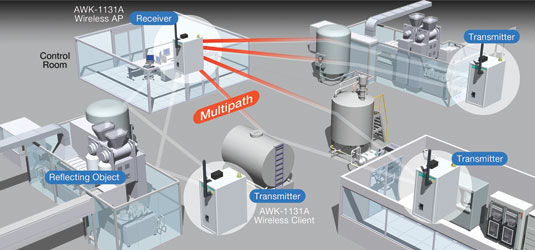

Ideally, the radio waves emitted by wireless transmitters will travel unimpeded to the intended receiver, which is usually what happens in the typical home, coffee shop, or office environment. Industrial automation sites, however, are a whole other ballgame, since the typical factory environment includes many metal obstacles that can seriously degrade the signal. Undesirable effects include reflections off large objects, scattering due to small objects, diffraction from sharp objects, shadowing from solid objects, and Doppler effects from moving objects. When confronted with so many obstacles, multipath fading shows up.

Multipath fading

Multipath fading occurs when the radio signal is split into multiple signals, each of which is affected by the environment in a different way, and each of which could arrive at the intended receiver at slightly different times. The resulting signal could be deteriorated to such a degree that whatever information was present at transmission is no longer decipherable at reception. Consequently, multipath fading must be taken into account when designing or developing a radio communications system. Multipath fading occurs in factory environments that are subject to multipath effects, and when the radio transmitters and/or receivers are required to move around, such as is the case with AGV applications. When either the transmitter or receiver is moving, or other objects in the environment are moving, different versions of transmitted signals will arrive at the receiver out of phase with each other, causing the strength of the signal to vary and resulting in an overall degradation of the radio signal.

Interference caused by multipath effects

Multipath fading is one type of interference caused by multipath effects. Another type occurs when different versions of the same signal travel along paths with different lengths, and consequently arrive at the receiver at different times. Since the frequencies of the various signals will be slightly changed, the combined signal will be distorted. ISI (inter-symbol interference) can also occur with digital transmissions. ISI is related to reflected signals, and occurs when signals for different parts of the same data symbol are picked up by the receiver at slightly different times.

How to handle multipath effects

Understanding how to eliminate the interference caused by multipath effects is essential when using wireless communication in factory automation environments. In addition to large obstacles, such as the floors and walls inside factory buildings that cause reflection and result in multipath effects, metal equipment deployed in factories also poses serious obstacles that can degrade wireless signals. Moreover, since automation applications inevitably use moving equipment to improve efficiency, operators must take into consideration the multipath fading effects generated by the radio transmitters and receivers deployed on the moving objects. There are two ways to eliminate interference caused by multipath effects: OFDM and MIMO.

OFDM

OFDM (orthogonal frequency division multiplexing) works by dividing one digital signal into different low data rate parts on low data rate signal carriers. OFDM uses carriers orthogonal to each other to avoid interference, giving it the ability to transmit at a higher data rate by using multiple signal carriers. When the data to be transmitted on an OFDM signal is spread across different signal carriers, each carrier takes part of the load, thereby reducing the data rate handled by each carrier. The advantage of the lower data rate is that it makes the interference from reflections less serious.

Distributing data across a large number of carriers in an OFDM signal is paramount to playing the odds. That is, although interference from multipath effects will affect the signal transmitted by some of the carriers; it will only affect a small number of the carriers. In addition, error correction code can be transmitted via a different carrier than the data, which allows data corrupted during transmission to be reconstructed at the receiver end.

MIMO

MIMO (multiple-input and multiple-output) uses multiple transmitters and receivers to improve the performance of wireless communication. When multiple transmitters and receivers are used, simultaneous data streams can be sent, thus increasing the data rate. In addition, multiple transmitters and receivers allow greater coverage and longer distances between devices. The IEEE 802.11n standard uses MIMO to increase wireless data rates to 300 Mbps with 2 spatial streams and beyond.

In a typical communication system using antenna diversity or MIMO, four methods are often used to deal with multipath effects in environments that exhibit multipath fading. The methods include: time diversity, frequency diversity, spatial diversity, and path diversity.

IEEE 802.11n technology uses the spatial diversity method to counteract the multipath issue. If a specific antenna in the group suffers a severe transmission disruption, the spatial diversity method singles out the antenna signal that has suffered the least amount of transmission disruption, relatively speaking, and restores its function. The principle of this method lies in the belief that when multiple antennas are functioning independently while located in the same environment, the channels used by each antenna can be understood as uncorrelated with each other. Each channel may be subjected to multiple path or co-channel interferences, but the possibility of them suffering from the same type of variation is very unlikely. In order to solve the variability issue in each channel, the system uses internal algorithms that can reduce the variation of each channel and greatly improve its effectiveness to resolve multipath fading.

Electrical disturbances

Factory environments are characterised by harsh conditions that could damage wireless devices and interrupt wireless transmissions. Three common types of electrical disturbances are particularly crucial for mission-critical applications: ground loops, interference from DC motors, and ESD. We discuss each in turn.

Ground loops

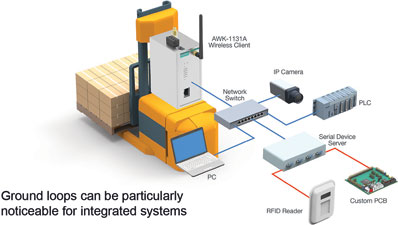

Ground loops, which are caused by unintended variations in the electric potential at different points in an application’s environment, can have a negative effect on communication signals and damage equipment. The effects can be particularly noticeable for integrated systems, such as AGV equipment, in which several different devices are attached to the vehicle. In this case, ground loops could interrupt the vehicle’s operation.

Interference from DC motors

The electromagnets and electrical currents used to rotate DC motors can cause discontinuous currents and electromagnetic interference (EMI) at the start and transition stages, affecting the quality of the power supply, the surrounding electromagnetic environment, and the operation of peripheral appliances.

ESD

ESD (electrostatic discharge) which results from the sudden transfer of static electricity between two objects with different electrical potentials is also important. Factory workers wearing rubber boots and gloves can easily accumulate high levels of static electricity, and friction between objects rubbing against each other can also cause ESD. Physical contact with wireless devices can discharge several kilovolts (kV) of static electricity and permanently damage internal circuitry.

Dealing with electrical disturbances

To ensure that a wireless connection remains active and works properly, wireless devices must be tough enough to withstand all electrical disturbances in factory environments. The effects of these factors can be mitigated by using products designed with galvanic isolation technology to prevent damage to the wireless devices.

Galvanic isolation

Galvanic isolation involves physically separating the electrical current in one part of a device from the electrical current in another part of the device to prevent unintentional interaction between the two parts. Although a variety of methods can be employed to implement galvanic isolation, the goal of all of the methods is to enforce the absence of DC paths between the parts of the system that need to be isolated from each other. In fact, most isolation methods eliminate all DC paths below 100 MΩ. Galvanic isolation provides three major benefits – circuit protection, noise reduction, and rejection of high common-mode voltage – and is considered to be the best solution for protecting against electrical disturbances.

The demands of high mobility

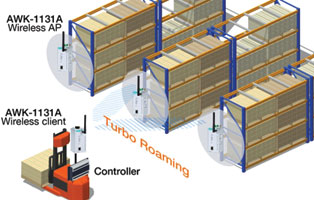

AGVs, unmanned shuttles, and other mobile equipment, are used in today’s factories to increase efficiency. In addition, operators avoid wiring and space constraints by using wireless devices to control and monitor their mobile applications. In all of these cases, achieving seamless wireless transmission is crucial to ensuring that the AGVs and shuttles achieve the highest possible level of mobility.

For mobile applications that use multiple access points (APs), roaming (also called handover) refers to when a client moves between two or more access points, with the speed of the mechanism used to implement roaming crucial to maintaining a usable wireless network. As the client physically moves from one AP to another, the signal strength of the first will drop while the signal strength of the second will increase, when the signal strength of the first AP drops below the signal strength of the second, we say that the client has roamed to the second AP.

Factors that affect the smoothness of roaming include the topology of the APs, the gain and coverage of the antennas, and the roaming threshold settings of the client. To ensure smooth roaming, users first need to take into consideration the route of the moving object, and then carefully plan the wireless AP deployment configuration.

Seamless roaming

The most crucial aspect of mission-critical wireless applications is ensuring uninterrupted communication between wireless clients and APs, even when the wireless client is roaming at a relatively high speed.

A standard roaming mechanism only starts scanning for the second AP when the first disconnects, which can take 3 to 5 seconds or more to process, and which is too long for critical industrial mobile applications. Such a long handover time can result in packet loss, which in turn can cause unmanned AGVs to temporarily lose contact with their control signal and then veer off course.

Ideally, mission-critical mobile applications require roaming times under 150 to 300 ms to ensure seamless wireless transmissions. The client-based roaming mechanism developed by Moxa is a proprietary technology designed to meet this strict roaming time requirement. To avoid packet loss, the wireless client actively searches for APs emitting a stronger signal, without waiting for a complete disconnection. This pre-emptive type of roaming mechanism can react faster to the roaming event and hence provide a much shorter roaming time compared to standard roaming.

Applications require comprehensive solutions

With so many critical factors associated with factory environments, system integrators are always on the lookout for the best comprehensive solutions to ensure wireless network reliability. Wireless devices must support several crucial features to ensure reliable wireless transmissions:

• 802.11n MIMO technology to improve the transmission and reception of multiple data streams. Not only can MIMO handle multipath effects, it can also increase the data rate up to 300 Mbps.

• Galvanic isolation for both the power source and antennas, since many different kinds of electrical disturbances can jeopardise devices and affect connectivity.

• Seamless roaming to ensure a smooth wireless handover from one AP to another in under 150 ms.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved