Most potential users of industrial wireless networks will probably pick one of the two mainstream wireless technologies and accept that the choice is mutually exclusive – either ISA100.11a or WirelessHART.

In many cases that selection may be as a direct result of their choice of DCS and into which wireless camp their DCS vendor falls.

In December 2012, when the ISA subcommittee on wireless convergence gave up on the possibility of convergence of these two industrial wireless standards, one of the rationalisations that they made was it would be highly unlikely that process industry plant operators would need to incorporate both types of wireless networks on a single site. Responding to our question, co-chair of the ISA100.12 WirelessHART Convergence subcommittee, Dick Caro, explained, “The conclusion of the ISA100 standards committee also was that it is highly unlikely that both ISA100 Wireless and WirelessHART will get installed in the same plant area anyway. Process industry users don’t work that way – they select a set of compatible suppliers for an installation and currently, this will preclude mixing wireless protocols.”

There is an ongoing initiative operating under the name of the Heathrow Group that continues to look at convergence paths for ISA100.11a, WirelessHART and WIA-PA, but the road to a single converged industrial wireless standard that embraces all three of these existing standards looks long and tortuous. In the absence of a converged standard it may be that wireless specialists and plant operators will develop their own 'convergence' solutions.

It’s not that simple

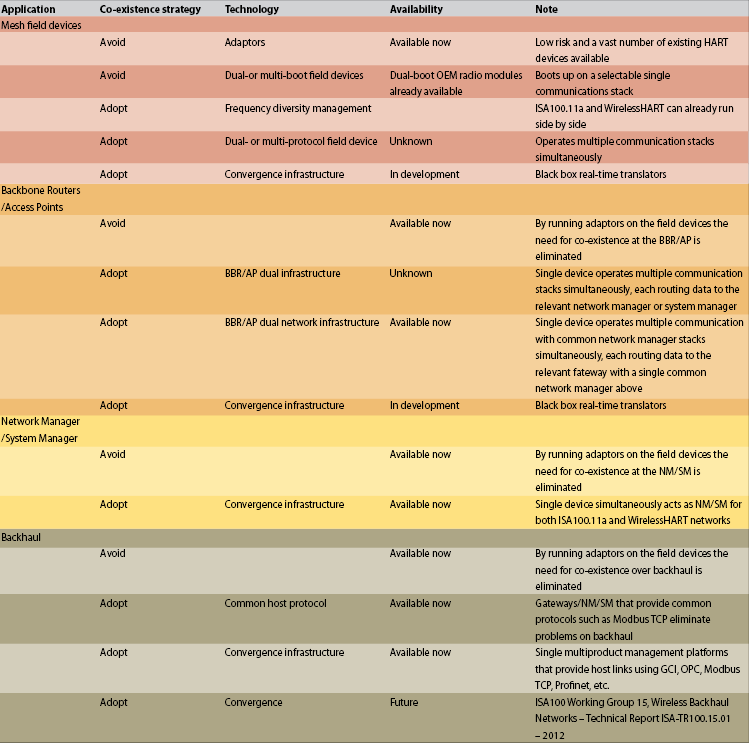

In the absence of a converged standard there may be scenarios where certain sensors are only available in one wireless technology or the other. Perhaps corrosion transmitters are only available on ISA100.11a or steam trap monitoring transmitters on WirelessHART. In this case the plant operator may consider the following choices:

* Avoiding dual technologies – Source a suitable wired instrument transmitter and add a wireless adaptor to suit the chosen wireless technology or

* Adopting dual technologies – Accept that he is going to have to consider implementing wireless networks of both flavours.

Avoiding dual technologies

Many of the major instrument vendors offer adaptors for integrating instrument transmitters into one of the two major industrial wireless networks. Deploying new traditional two or four-wire instruments with wireless adaptors means that the 'wireless' benefits of reduced wiring infrastructure are lost. However, there are compensating benefits, over and above the provision of a wireless measurement signal. These benefits accrue as a result of access to enhanced diagnostic information.

Honeywell’s OneWireless Adaptor is the only ISA100.11a adaptor currently certified by the ISA100 Wireless Compliance Institute1. HART Communication Foundation2 lists adaptors available from ABB, Endress+Hauser, MACTek, Dresser Masoneilan, NIVIS, Pepperl+Fuchs and Siemens.

The OneWireless Adaptor (Figure 1) converts field devices that use the HART protocol into devices that can transmit data over an ISA100.11a-compliant wireless network, while Emerson Process Management’s Smart Wireless THUM Adaptor will join any two or four-wire HART device into a WirelessHART network.

Adopting dual technologies

Operating ISA100.11a and WirelessHART on the same plant means that the plant operator is going to have to consider aspects such as:

* Mesh network – How well will ISA100.11a and WirelessHART play together?

* Access Points, etc. – Can they share access points, backbone routers, network managers, system managers?

* Backhaul – Can they share wired and/or wireless backhaul infrastructure?

* Total cost of ownership – What inventory holding and skills base rationalisation can be achieved?

Mesh network

The physical layers of both ISA100.11a and WirelessHART are based on IEEE802.15.4, operate in the 2,4 GHz spectrum and employ some form of frequency hopping. That means that signals in the two networks do have the potential to interfere with each other.

There are also other users of the 2,4 GHz spectrum that may add to the potential for interference. These include devices using other 802.15.4-based technologies (ZigBee and MiWi), devices using various versions of 802.11, including Bluetooth and Wi-Fi and even microwave ovens.

Fortunately both ISA100.11a and WirelessHART incorporate some degree of frequency diversity management to mitigate interference. ISA100.11a offers channel blacklisting along with three possible channel hopping schemes (slotted hopping, slow hopping and hybrid (adaptive) hopping). WirelessHART incorporates channel blacklisting and a non-configurable pseudo-random channel hopping scheme that results from a combination of frequency-hopping spread spectrum and direct sequence spread spectrum technologies.

With appropriate configuration using the frequency diversity management tools in each, mesh co-existence of the two technologies should be viable.

An alternative approach that has been tabled by some users is that field instruments could be supplied with both ISA100.11a and WirelessHART communication stacks embedded in their firmware, with the desired option being configured during instrument provisioning. While it seems that many instrument vendors are unlikely to voluntarily provide such dual-boot solutions due to the higher costs involved, wireless specialist NIVIS has already brought to market the VersaNode 210 and VersaNode 310 dual-boot radio modules ready for vendors to incorporate into their transmitters.

Access points, etc.

For the purists, ISA100.11a mesh networks connect to the backbone at Backbone Routers (BBRs) whereas WirelessHART mesh networks connect to the backbone at Access Points (APs), which are often combined with Gateways. For the sake of simplicity this article will refer to both as APs.

Dual-boot VersaRouter modules from NIVIS represent a significant step in the direction of providing a common AP for both the industrial wireless networks. These devices will communicate with the wireless mesh network over the selected boot protocol and connect to an Ethernet backhaul using the Modbus TCP protocol.

Nivis also are already offering dual- or multi-infrastructure APs available to OEMs that will run both of the subject industrial wireless protocols simultaneously. These comprise either one or two radios with both protocol stacks.

These dual-stack APs can be implemented in architectures where data relating to each protocol is routed to its own Network Manager (NM) or System Manager (SM). In this architecture the two managers are not able to optimise channel usage and time slots. Improving on this idea Nivis has developed its VersaManager 3000. This provides a manager which combines the capabilities of both an ISA100.11a NM and a WirelessHART SM. And by combining the two in one device it means that routing, traffic, channel allocation and time slot usage is under the control of one intelligent common network manager, so that cross-network interference can be completely eliminated and a single interface can be provided to the host or DCS via industrial protocols such as GCI, OPC, Modbus TCP, Profinet, etc.

Backhaul

Once the data destined for the backhaul is reduced to a protocol like Modbus TCP there is no practical reason why multiple APs communicating with wireless mesh networks over different industrial wireless protocols should not operate simultaneously.

Backhaul links do not have to comprise only physical links such as copper or fibre, but may also utilise wireless. And while standards convergence may have failed in terms of industrial wireless protocols in the field, the ISA100 Working Group 15, Wireless Backhaul Networks, succeeded in releasing Technical Report ISA-TR100.15.01 – 2012, Backhaul Architecture Model: Secured Connectivity over Untrusted or Trusted Networks, in late October 2012. This Technical Report proposes a model and common vocabulary for interconnecting automation system elements over untrusted backhaul networks that can be applied to both wired and wireless backhauls and embraces simultaneous and secure transmission of data from multiple diverse devices including ISA100.11a and WirelessHART.

While much work remains to be done before the proposals of ISA100 Working Group 15 become a reality they certainly provide an idea of the direction in which developments may go in terms of shared backhaul infrastructure.

Total cost of ownership

Considering the options of avoiding or adopting dual technologies as described in this article it is almost inevitable that until truly converged backward-compatible solutions exist the TCO (Total Cost of Ownership) of the avoidance option will remain below that of operating dual industrial wireless network technologies for the following reasons:

* Fewer unique components – resulting in lower inventory carrying costs.

* Less diverse technology to maintain – resulting in lower man-power costs.

* Less technological risk – resulting in lower lifecycle costs.

If the need to run both technologies cannot be avoided then TCO can probably be minimised through the adoption of dual-boot technologies.

References

1. ISA100 Wireless Compliance Institute, Website: http://www.isa100wci.org

2. HART Communication Foundation, Website: http://www.hartcomm.org/

3. NIVIS, Website: www.nivis.com

| Tel: | +27 11 543 5800 |

| Email: | [email protected] |

| www: | www.technews.co.za |

| Articles: | More information and articles about Technews Publishing (SA Instrumentation & Control) |

© Technews Publishing (Pty) Ltd | All Rights Reserved