Fire safety is serious business. No matter the industry, the damage caused by a fire could be catastrophic for business. But how do you mitigate the risk? The Fire Protection Association of Southern Africa recommends a fire risk assessment be done when any meaningful changes occur. Meaningful changes can include the increase or decrease of the number of employees, any changes to the building structure, or if any processes in the building change.

Substation protection

Substations are unique in that they offer particular fire risks and need to be analysed separately from the general business model. Alien Systems & Technologies has developed a unique risk assessment approach to substation fire protection using an understanding of substation fires.

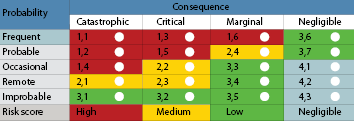

The risk reduction procedure developed by AST uses the workplace risk assessment control (WRAC) chart and qualitative guide:

Probability

* Frequent – likely to occur often during the life of an individual item or system, or very often in operation of a large number of similar items.

* Probable – likely to occur several times in the life of an individual item or system, or often in operation of a large number of similar items.

* Occasional – likely to occur sometimes in the life of an individual item or system, or several times in operation of a large number of similar items.

* Remote – unlikely but possible to occur sometimes in the life of an individual item or system, or can be reasonably expected to occur in the life of a large number of similar components.

* Improbable – so unlikely to occur in the individual item or system that it may be assumed not to be experienced, or it may be possible, but unlikely to occur in the life of a large number of similar components.

Consequence

* Catastrophic – death, loss of system or plant, release to the environment, such that significant public interest or regulatory intervention occurs or reasonably could occur.

* Critical – severe injury, major system damage or other event which causes some loss of production, unplanned localised damage to the environment, affect other areas or could have resulted in catastrophic consequences in different circumstance.

* Marginal – minor injury, minor system damage, minor confined and non-damaging environment exposure or other event.

* Negligible – less than the above.

Points of possible fire risks in substations include: HT cabinet enclosures, MCC cabinet enelosures, VSD cabinet enclosures and bunched electrical power cables. The listed equipment, if damaged in the event of a fire, would affect the electrical power reticulation system of a mine, plant or building. These substations are designed to provide electrical power continually in order to maximise production and revenue income. Should they suffer a disruption or catastrophic event, not only are the recapitalisation costs high but losses in production are likely to be severe.

Likely causes of fire in the substation

Given the electrical energy present in substations, there is always the potential for fire in spite of every care to prevent faults leading to ignition. The primary cause of fire is high levels of energy sufficient to increase temperature of materials to a point of fire ignition.

Generally this occurs in cable termination compartments leading out to motors and other equipment. Where cable is terminated within cabinets and the crimp on the lug occasionally overloads and increases in temperature to a point where fire occurs. Another common source of fire is at the spring loaded connection point between the breaker compartment and spouts leading to the bus bars. Occasionally the spring loaded connection mechanism is weakened or damaged from misaligning of the breaker and spouts. The weakened spring leads to a faulty connection that causes overheating leading to a possible fire.

However, there are other sources of fire within substations. Sometimes rodents can get inside electrical cabinets that result in an arc flashing that has enough energy to cause other materials to ignite.

Should the aforementioned events happen without any intervention, fire could ultimately destroy the substation. Furthermore, fire from the substation can travel along the routed cables to motors and other equipment. Usually transformers are nearby substations and they can also form a secondary fire.

Using the WRAC chart, fires within substations happen ‘occasionally’ given the inherent high energy present. Should they happen without intervention, the consequences could be catastrophic.

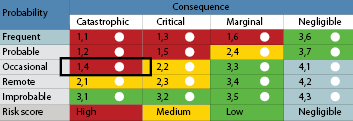

When the probability is occasional and the consequence in catastrophic then the WRA risk score is high, therefore measures are required to reduce this to low or negligible. This includes in depth analyses of the construction of the substation, the probability control measures and the consequent control measures.

Method of fire protection

The method of fire protection best suited to switchgear operations works as follows:

Detection

The fire detection system should detect a fire at its true incipient stage, before the advent of smoke, to confirm the presence of combustion as early as possible and facilitate the operation of a fire extinguishing system. The system should alert a control and alarm signalling system and should also have a monitored detection system for fault and fire. The detection system should conform fully to an internationally accepted engineering standard.

To detect fire combustion at its true incipient stage, a Cirrus Pro Aspirating Detection System could be used. Cirrus Pro employs a sub-micron combustion particle detection ‘cloud chamber’ that detects the combustion particles that occur before smoke. This detector is ideal for dusty mining and plant environments as it is impervious to false alarms caused by dust particles. The key benefit is a very early warning of fire, which means preventative action can be taken before any catastrophic event occurs. Utilising a point type optical smoke detector arrangement will confirm the presence of fire.

Where no ceiling is present and the substation is covered by a sheet metal roof, a system such as Pyrogen could be used inside the electrical cabinets. Fire detection needs to be in the room and all cable trenches. Should a cable room form part of the risk area, fire detection needs to be included. All detection systems need to be designed and installed to conform to a recognised international engineering standard such as SANS/ISO 10139 & SANS 369 Parts 1 & 2.

Extinguishing

In order to extinguish a fire as quickly as possible an automatic system should be used. The extinguishing system should be fully approved by a third-party approval authority to an internationally accepted engineering standard. It should use a non-toxic, human and environment friendly medium that is sustainable against impending global warming regulations. It also makes sense to utilise an extinguishing agent that has a low refill cost and one that will not adversely affect the protected equipment and processes.

For a substation room that has a ceiling construction, a Pyroshield inert clean agent gaseous extinguishing system could be used or a Pyrogen in-cabinet aerosol system. A room integrity test needs to be carried out to validate the hold-time for the Pyroshield Gas as per the room’s natural leakage. The key benefit here is a one size fits all fire extinguishing system that is inert to harmful human toxic by-products and environmentally damaging hydrofluorcarbons. A local handheld fire extinguisher should also be installed within the substation as per local regulations. The type and number should conform to local standards and regulations.

Other measures

All louvers should be sealed in the event of first detection of a fire and all air conditioning devices must be tripped. All cable trenches must be properly sealed with a fire rated medium of at least one-hour or as per local standards and regulations. All detection, alarm and extinguishing circuits are to be monitored for fire and fault. The substation fire protection system should operate a local audible and visual alarm system, normally a local sounder on first detection and a second distinguishing audible sound on second detection. The substation fire protection system then needs to report to a central 24-hour manned operations security room, and wherever possible, a local fire brigade.

Recommendations for policy and procedures

The Fire Protection System should form part of the safety policy and procedures for any substation. The owner should visually check the system once a month for any faults reported on the control panel and anything that might appear out of the ordinary. The owner should immediately report to a competent fire engineering contracting company of any concerns or faults. A trained and competent fire engineering company should be contracted to inspect the system on a three-month basis. It should check that the system is fully operational in terms of its design and report immediately to the owner and make corrective actions in the event of a fault. Should any physical alterations be made to a substation, a review on the fire protection system must be done to see if its performance has been compromised. Appropriate actions should be made after this review. For any gaseous extinguishing system, a mandatory annual room integrity test should be carried out as per SANS/ISO1520 Part 1.

The impact on the risk score of the substation:

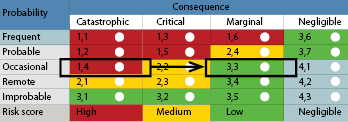

By following the aforementioned steps to control probability one can reduce the probability of a fire, however, given the inherent fire potential due to the high levels of energy plus the unpredictable nature over the escalation of a fire, the probability score remains at occasional. Installing a fire detection and extinguishing system reduces the consequences to marginal.

For more information contact Alien Systems & Technologies, +27 (0)11 949 1157, [email protected], www.astafrica.com

| Tel: | +27 11 949 1157 |

| Email: | [email protected] |

| www: | www.astafrica.com |

| Articles: | More information and articles about Alien Systems & Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved