Sappi is a global company focused on providing chemical cellulose, paper-pulp and paper-based solutions to customers in more than 100 countries. Its chemical cellulose products are used worldwide by converters to create viscose fibre for clothing and textiles, acetate tow, pharmaceutical products and a wide range of consumer products. Its range of paper products includes coated fine papers, casting release papers, newsprint, uncoated graphic and business papers, premium quality packaging papers and tissue products.

Like all producers in the pulp and paper industry, its flow application requirements are among the most challenging of any. The production streams typically vary between high and moderate temperatures and pressures, have high to low flow rates, have high noise levels and contain both dissolved and suspended solid materials and various harsh chemicals. Process noise can be the biggest challenge in accurate and stable flow measurement at pulp and paper mills.

Achieving accurate, stable flow measurement

Process noise results in a low frequency oscillation in the output signal, varying from as little as 2 to as much as 50% of the full scale value. The noise level is a function of particle size, particle hardness, flow velocity and EMV influences from other electronic components. As each of these increases, the noise level increases.

Process noise is recognised in two forms:

* 1/f noise, which means the lower the magmeter coil excitation rate the greater the potential for process noise to disrupt the flow measurement. An increase in stock consistency increases 1/f noise and chemical additions close upstream of a magmeter exhibit 1/f characteristics.

* Electrode impingement, which is a mechanical disturbance of the electrode interface of process fluid with the electrode surface. This causes the electrode signal to spike up to several times its normal magnitude for a temporary time period. This is typical in most slurry and in heavy black liquors.

* The ABB FSM4000 electromagnetic flowmeter, also known as the ‘AC Master’, is an AC excitation flowmeter ideally suited to pulp and paper applications. It is the heavy-duty flowmeter for unsurpassed performance in applications with high solids, pulsating flows, low conductivity or other noise. Its AC technology easily manages noisy applications, is unaffected by changing flow conditions and ensures continuous non-pulsed measurements at a fast rate.

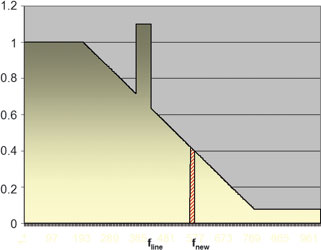

The FSM4000 System’s AC magnet coil excitation operates at a much higher excitation frequency than the line frequency (or pulsed DC field). In addition, it is very selective, due to its narrow bandwidth filters, which means only a small noise frequency range can have an effect. The frequency was chosen so that the noise components themselves are small in amplitude. This approach dramatically reduces the noise effects without requiring any increase in power. Furthermore, the flow signal is integrated continuously, resulting in minimised noise levels and a faster response time.

Sappi installed its first AC Master on thick stock flow at its Enstra plant in 2004. “We could see an immediate stabilisation in the measurement,” says Morne Van der Merwe, mill instrument engineer at Sappi Enstra. The flowmeter is still working perfectly in the same application. With an accuracy of 0,5% of the flow rate, achieved using advanced digital signal processing, the ABB FSM4000 AC Master sets a new standard for EMF technology. “From time to time we do a drop test to measure the accuracy and they are very close. Better than we expect,” says Van der Merwe.

The AC Master is the flow product of choice for the pulp and paper ‘Dirty Dozen’ applications. Sappi Enstra uses the AC Master on its stock prep, wet end paper machine side and all pulp transfers. “Anything to do with pulp flow, we only use the AC Master,” says Van der Merwe. Enstra is not the only mill to recognise the advantages. When Sappi Saicor embarked on its Amakhulu project in 2006, the AC powered flowmeter was the first choice for pulp flow applications. It was preferred over the pulsed DC meter, which samples the flow rather than constantly measuring it. The meters are currently still in operation. Sappi Ngodwana’s GoCell project, which is converting the existing plant into a cellulose mill like that at Saicor, will also be using the AC magnetic flowmeters on all pulp applications.

The extended diagnostic functionality continuously checks the AC Master’s own electrodes, coils and interconnecting cables, as well as signal quality and deviation of the measuring functions as compared to the values during original calibration. The device diagnostics allow the user to react to critical events at an early stage, increasing productivity and minimising downtime. “It definitely helps with maintenance,” says Van der Merwe.

“The instrument will tell you what the errors are and then it is very quick to resolve,” says Shaugn Osler, senior sales engineer for ABB Measurement Products. “The ease of installation and commissioning saves the user time and money. The AC Master requires no zero adjustments, uses a universal converter and has user-friendly configuration menus.”

“With the current resource shortage, the last thing you want is an instrument that is difficult to install. The installation is very quick. The electrical and the mechanical installation obviously take the longest. Once that is done it literally takes just a few seconds to get the meter going,” concludes Van der Merwe.

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved