The new O2I multi-code reader from ifm electronic convinces with its high resolution, short evaluation time and quick set-up, all of which fulfil the requirements placed on modern components for high-performing process automation.

Fast, robust and future orientated

The O2I, which made its début at Hannover Messe 2019, is an optimal solution for precise requirements. The technical data includes image resolution four times as high, a 10-times faster code evaluation time and the obligatory real-time Ethernet support. This latest generation of the multi-code reader therefore meets all the requirements for sustainable, instantaneous and reliable product registration, identification and tracking. Thanks to its powder-coated die-cast zinc housing, gorilla glass protecting the lens, and M12 Ethernet connectors made of stainless steel, the O2I achieves the protection class IP65 i.e. optimally prepared for use in demanding industrial environments.

Flexible and quick integration into the work environment

It is clear from the beginning that the O2I is designed for maximum efficiency: within just a few seconds it adjusts itself to its work environment. One push on the teach button is enough, and the multicode reader automatically begins with focussing, exposure setting and code type recognition. Optionally equipped with standard, wide angle or telephoto lens, the O2I can read all common 1D and 2D codes within a distance of 35 up to 1000 mm, as well as at an angle of inclination of up to 45 degrees and therefore adapts flexibly to any structural condition.

Easy configuration via app

The basic integration of the device into the work flow and infrastructure is accomplished easily thanks to the matching smartphone app for iOS, Android and Windows. With this, for example, the trigger function of the camera can be set and the intended network parameters defined. As soon as the settings are adjusted to the individual requirements, the app creates a DataMatrix code. When this code is held into the reader’s field of view, the configuration is automatically adopted.

Once the instrument is configured with a few steps, it processes codes with a frequency of up to 40 Hz and with a speed of up to 7 m/s.

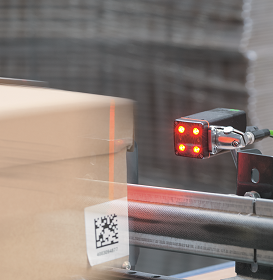

Whether the information is printed on the surface, engraved by laser or dot-peened into metallic products is unimportant. Thanks to optional integrated red light or infrared illumination and polarisation filter, the O2I can easily deal with reflecting surfaces, varying colours and changing ambient light.

The same goes for the omnidirectional recognition of several different codes per image, due to the auto-find code function. Together with the award-winning Vision Assistant software, the O2I shows off its strengths. In the software, the user can easily classify identified codes and assign them to a defined automatic process via various logic functions. The live image and extensive visualisation of all settings provide an optimum overview for the user.

Memory stick saves costs and makes reproduction easier

Once the user has created a process, it will be saved on an exchangeable USB memory stick which is built into the multicode reader. A solution that has several advantages: firstly, the configuration can be passed on in case of a device exchange; secondly, using the same method, identical process controls can be transferred to several devices. At the same time the use of the device also reduces costs for further components, as the procurement of an expensive external evaluation unit is no longer necessary.

With the O2I, ifm meets all the requirements for a sustainable multi-code reader. Easy to integrate into the existing network and plant infrastructure, powerful in code reading and equipped with a large range of functions, the instrument takes product tracking to a new level.

| Tel: | +27 12 450 0400 |

| Email: | [email protected] |

| www: | www.ifm.com/za |

| Articles: | More information and articles about ifm - South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved