Currently, in mining applications, radiometric measurement has been the only way to measure the density of slurry. Until recently, and due to the harsh and abrasive environment of slurry, no other measuring principle could work. This has recently changed due to the use of tuning forks (FTL 50) in conjunction with density computers (FML621).

The reason why radiometric density is unpopular is not because the principle of measurement does not work – on the contrary it works well and with very few issues. The problem with radiometric density measurement is the red tape that surrounds the measurement point. To have radiometric measurement a site needs to conform to certain local and international standards. A radiation officer needs to be permanently on site in case of an accident. Training around safe practices with radiation needs to be performed and complex and costly transportation regulations need to be followed. These are some of the challenges that plants face when it comes to radiometric measurement for density.

This process is becoming less challenging with the introduction of a tuning fork that can measure slurry density. Depending on the slurry application, correctly installed tuning forks can now last longer than 12 months before they require any maintenance.

The tuning fork principle

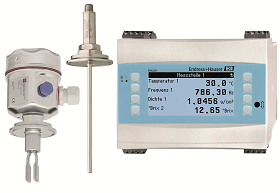

Vibration limit switches are mechanical systems vibrating at their resonant frequency. A piezo drive, the core element of the sensor, generates drive impulses that are transferred to a stainless-steel tuning fork, the only part of the system which comes into contact with the product. Due to this well-known piezo effect, it is possible to make the tuning fork resonate and measure the shift in resonant frequency. The limit switch also analyses the resonant frequency at which the fork vibrates. Thanks to this cleverly employed technical feature, limit switches have reinvented themselves as fully-fledged density measuring instruments, which fulfil user requirements for information directly from the process and provide a cost-effective alternative to established measurement methods, such as manual sampling. Parameters such as conductivity or dielectric constant, do not interfere with the function of the sensor. However, temperature compensation is recommended to achieve highest accuracy. If a pressure changes in the process by more than six bar, then pressure compensation will also be required.

The measuring principle is based on the fact that the resonant frequency of the tuning fork depends on the density of the product, the process temperature and pressure. Changes to the resonant frequency are directly affected by the density of the material. Materials with a lower density such as liquefied gas give rise to higher resonant frequency than materials with a greater density such as water. The density of the medium can be accurately calculated using mathematical formulae depending on the resonant frequency, temperature and pressure. The frequency shift is, therefore, used to measure changes to density levels caused by different liquids or concentrations. Combined with a density calculator, the corresponding density value of the medium can be calculated from the resonant frequency in a reliable and reproducible manner. Fluctuating process temperature near the tuning fork should also be measured by a temperature sensor, which is then recorded and compensated in the density computer. Therefore, influences on the density value are taken into account.

Factors to consider when installing a tuning fork in a flow density application include:

• Vertical installations are recommended.

• Eliminate air bubbles.

• Eliminate build up while empty.

• Low (0-2 m/s) velocity.

• Fine slurry particles (0,15 mm).

For more information contact Dhiren Naidoo, Endress+Hauser, +27 11 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved