Design engineers at Zwick have solved the ongoing problems experienced with valves on sulphur units. Typical valve problems on large bore line sizes range from seizing of the packing to severe seat damage when valves need to be operated after long periods of inactivity. Valves should be specified as steam jacketed as this is a standard mandatory type of valve requirement.

Generally a standard valve may be suitable in an ideal line where there are never any shutdowns or upset conditions, as once the valve’s body temperature has reached that of the hot sulphur or tail gas passing through it will not allow for any solidification, however, in an upset condition were the valve body cools down with sulphur cooling also, then this will solidify in the bearing/shaft areas, which will consequently generate a seizure of these elements.

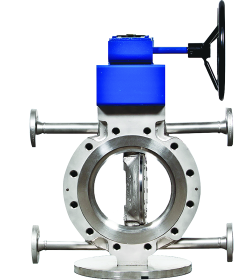

Based on international experience, Zwick engineers recommend the use of steam jacketed valves as these would maintain the critical areas under a constant temperature, thus eliminating any potential seizure. The company is capable of supplying valves in both wafer and double flanged style with steam jackets, and we can also apply a steam traced trim (stem and disc).

Zwick Tri-Con series valves come with bearing protectors, which reduce the ingress of the medium into the critical areas, which coupled with the bearing flush purge ports, constitute a true cleansing and protection of these critical areas.

The following explanation highlights the technical differences between the Zwick Tri-Con valve and other types ranging from double eccentric to unjacketed valves, which will fail in this type of application.

The Tri-Con series is a specially designed process isolation, on/off and control valve, which has a wide range of application uses limited only by that of the actual materials used, in fact Zwick manufacture valves for applications which range from -196ºC up to +815ºC. Valves can be manufactured in any machinable form of alloy for specific client requirements.

The Zwick Tri-Con series is a triple offset valve with true cone in cone design that eliminates any rubbing of the seats, hence eliminating any wear and tear which would generate leakage. This is technically not possible for other typical high-performance valves, for instance double eccentric design where rubbing sealing in the last 15-18º will generate leakage as the time goes by. Double eccentric valves are not designed for these severe applications; therefore any attempt to use them may result in problematic outcomes.

Self-centring disc: with its unique self-centring temperature compensating disc, the Tri-Con series construction guarantees the optimal position of the laminated seal against the seat. Jamming due to thermal expansion is therefore eliminated.

Torque transmission with keys: the disc is keyed to the shaft and not pinned, providing equal torque transmission and eliminating the danger of pins sheering off.

Ideal lamination and disc design: the strong disc with its elliptical supporting surface offers the best fixing of the lamination. Zero leakage is achieved by the special machining of the lamination.

Supporting bearing bushing: the optimal position of the bearing reduces the bending of the shaft. This guarantees bi-directional tightness under maximum pressure.

Other features include:

• Metal seating.

• Full bi-directional shutoff tp API & DIN, ZERO Leakage.

• Size range DN50 to DN1800.

• Friction-free opening and closing.

• Vacuum tight.

• Laminated seal and seat made of stainless steel.

• Anti-blow-out shaft to API 609.

• Fire-safe acc. To BD 6755 and API 607 for both flow directions.

• Fugitive emission control according to TA-Luft II.

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved