Efficient operation of essential assets is key in achieving productivity and operational targets. Facilities, manufacturers, operators, and producers can move forward in planning for their output by having smoothly functioning assets.

Every industrial facility (either discreet or process) comprises of around 5% critical assets such as generators, turbines, compressors etc. These critical assets are nearly always installed with online protection systems, and in most cases, with online prediction systems as well. This equips operators and maintenance personnel with tools that inform them of their asset status round the clock, throughout the year.

Around 25-30% of the assets such as pumps, heat exchangers, non-critical compressors, and more are classified as essential assets. Failure of these assets can impact significantly on plant throughput. Such assets are usually not instrumented for real-time monitoring. Current industry practices in maintaining such assets are based on weekly, monthly or quarterly preventive maintenance rounds, as well as predictive maintenance processes done through portable handheld vibration analysers based on asset classifications. Without online monitoring, these assets are often subjected to reactive maintenance activities and consequently unexpected downtime and higher maintenance costs.

Costly repairs without prior notice of failure

According to the US National Response Centre, it costs approximately 50% more to repair a failed asset than if the problem had been addressed prior to failure. Studies from InTech 2012 show that 70% of most maintenance budgets are reserved for essential assets, while 3,5% of unplanned shutdowns or slowdowns are caused by the breakdown of essential assets.

Take for example the role of an operator tasked to monitor and prevent the breakdown of a pump. Once the pump he is operating starts to show signs of degradation, the operator has the skills and the experience to determine that there is a problem with the pump, which needs to be fixed. The next logical step for the operator is to contact the maintenance team. Now, time becomes a critical component to the maintenance process as the teams try to identify what needs to be fixed and execute the repair.

Improving reliability with essential asset monitoring

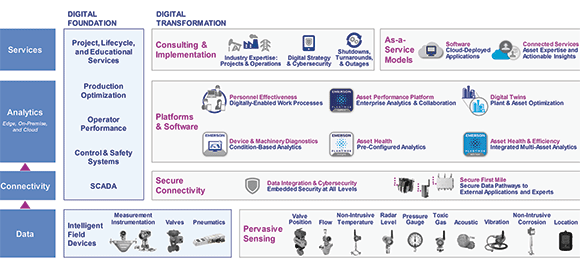

Considering these factors and risks with essential assets, Emerson has been providing solutions to aid organisations maintain their assets. Through the methodologies of Operational Certainty and Project Certainty, Emerson equips industrial organisations with proven approaches of top quartile performers.

Project Certainty is a proven approach to achieving performance goals to move strategic engineering decisions into the earliest project stages. Operational Certainty, on the other hand, is a methodology that helps organisations to pinpoint the cause of poor performance, enabling them to prioritise actions that can yield the greatest improvement and establish a scalable work plan.

With the advent of IIoT solutions, Emerson provides practical technologies that also deliver visibility to operations, maintenance, and reliability teams for essential assets. These innovations provide data coverage through instrumentation and also through the broad range of analytics software and platforms included in Emerson’s Plantweb portfolio. Through this digital ecosystem, organisations can transform operations with measurable improvements in reliability, safety, energy management, and overall operations.

The next step of Emerson’s IIoT solutions involves relaying the health analytics of essential assets to the relevant person in the time required through the Plantweb Optics platform. Relevant operators can access the critical data through desktop tablets and smartphones, with a connection to the CMMS system for work order generation.

These IIoT applications provide support for essential assets and effective monitoring for plant teams through the optimisation of work routines, and prioritisation of activities that are no longer time-based, but now condition-based. Operators can therefore be informed in advance when an issue with an essential asset is discovered. With reduced reactive maintenance, plant operations can now enjoy machinery uptime, enhanced production, reduction in unnecessary inventory and better safety implementation.

For more information contact Devesh Roopnarain, Emerson Automation Solutions, +27 11 451 3700, [email protected], www.emerson.com

| Tel: | +27 11 451 3700 |

| Fax: | +27 451 3800 |

| Email: | [email protected] |

| www: | www.emerson.com |

| Articles: | More information and articles about Emerson Automation Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved