Foxboro’s vortex flowmeters designed for harsh process environments

April 2019

Flow Measurement & Control

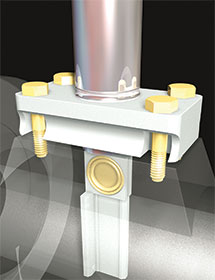

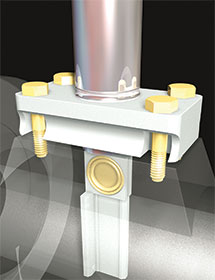

The Foxboro Model 84 series intelligent vortex flowmeters are among the best performers on the market and designed for flexibility and reliability in harsh process environments. Available in flanged (84F), wafer (84W), and sanitary (84S) configurations, there is a meter for nearly every application. The 84S meets 3A sanitary requirements per specification 28-03.

The accuracy of the Model 84 excels in liquid, gas, and steam applications for process temperatures up to 430°C. These instruments incorporate the patented DirectSense technology with Flexible Tuning for outstanding performance. DirectSense technology eliminates unreliable, mechanical sensor linkages used in some other vortex meters. The result is a simple, reliable design that is more sensitive to flow and less sensitive to noise. Combined with Flexible Tuning, the Model 84 has wide flow range capability. Other features and benefits include:

• Real-time Reynolds number correction.

• Correction for piping effects.

• Adaptive filtering for noise rejection at varying flow rates.

• Automatic low flow cut-in.

• Tuneable for specific operating conditions.

• K-factor corrected for temperature.

• HART communication protocol for measurement integration.

Accuracy in the field

The meters utilise Flexible Tuning to compensate for operating influences and maintain accuracy under conditions outside the calibration laboratory:

• Process piping: installation parameters such as pipe bore, location of valves, proximity to elbows, etc.

• Process temperature: correction for K-Factor shift due to change in the process temperature.

• Operation at low flow rates: an algorithm, utilising values for density and viscosity is embedded in the meter to correct for nonlinearity in K-factor at low flow rates.

• Low flow cut-in: eight user defined selections of LFCI. The instrument also includes an automatic low flow cut-in feature that can be configured to automatically select LFCI.

• Signal conditioning: a digital smoothing algorithm can be enabled to condition the raw vortex signal. This results in improved performance, particularly at low flow.

• Low and high frequency filters: these filters are set automatically based on the flowmeter configuration.

• Adaptive filtering: the meter provides an adaptive mode which automatically adjusts the high and low frequency filters.

For more information contact Johan van Jaarsveldt, EOH, +27 87 803 9783, [email protected], www.eoh-pas.co.za

Further reading:

Mastering inline LNG flow monitoring

Flow Measurement & Control

[Sponsored] As global demand for cleaner, more flexible energy sources continues to rise, liquefied natural gas (LNG) stands at the forefront of the energy transition. Engineered for excellence in cryogenic environments, the Anton Paar L-Cor 8000 flowmeter redefines inline LNG flow monitoring.

Read more...

Magnetic-inductive flowmeter with effective compact electronics and IO-link

Instrotech

Flow Measurement & Control

KOBOLD has combined two of its proven components, the successful type MIK magnetic-inductive flow meter and the popular U-PACE compact electronics, creating an exciting new compact flow instrument at the best price.

Read more...

Dosing chlorine gas safely and sustainably

Flow Measurement & Control

Chlorine gas is central to a range of industrial processes but is highly dangerous. The solution is the deployment of a system solution for chlorination from Lutz-Jesco.

Read more...

Oil monitoring solution drives performance gains for paper mill

SKF South Africa

Flow Measurement & Control

By integrating real-time monitoring with precise flow control, SKF’s Flowline oil monitor meters have significantly improved the flow rate control and performance of oil circulation lubrication systems installed on a paper mill.

Read more...

Flow measurement in mobile applications

ifm - South Africa

Flow Measurement & Control

The SU Puresonic Mobile ultrasonic sensor from ifm is characterised by its displayless design and high temperature resistance. It is ideal for mobile applications and processes with permanent media temperatures of up to 120°C.

Read more...

Optimising water quality in a building cooling system

ifm - South Africa

Flow Measurement & Control

A leading company in industrial water management has installed water treatment systems that not only optimise water quality but also help customers to improve their processes, thanks to the new insights and actions that can be generated based on the process data collected.

Read more...

New uncompromisingly simple flowmeter line for processes

Endress+Hauser South Africa

Flow Measurement & Control

The demand for simplicity in commissioning, operation and maintenance in industrial process plants has increased significantly in recent years. The new Proline 10 range of flowmeters from Endress+Hauser meets this requirement without compromise, because simplicity is the top priority.

Read more...

Rotork joins Rockwell Automation’s Technology Partner Programme

Flow Measurement & Control

Rotork has entered into the Rockwell Automation Technology Partner Programme, marking a significant step in expanding the company’s presence within the industrial automation landscape.

Read more...

Loop signature 29: Averaging or surge level control

Editor's Choice Flow Measurement & Control

There are many processes where it is undesirable for the load to suddenly change quickly, for example in the paper industry. Examples of level control have involved reasonably fast tuning. An example of a level loop tuned this way and responding to a step change in setpoint is given.

Read more...

A reliable water supply: The make or break in building metros across South Africa

VEGA Controls SA

Flow Measurement & Control

South Africa’s urban centres encounter substantial water supply challenges. Maintaining stable water infrastructure is essential for the health, economic vitality and well-being of communities.

Read more...