Conveyor systems for grain applications

February 2019

Motion Control & Drives

BLTWorld offers dependable solutions for specific problems at the transfer points of conveyor systems in bulk materials handling, for example, grain in the food and beverage industry.

“ScrapeTec Trading’s German-engineered products have been specially developed for the prevention of dust formation and material spill, and for more efficient belt cleaning at critical sections along the conveyor route and transfer points,” says Ken Mouritzen, managing director, BLTWorld, distributors for ScrapeTec Trading in Africa and the Indian Ocean Islands. “AirScrape, DustScrape and SpeedScrape systems, which are easy to assemble and operate, form an important part of our custom-designed solutions service, to meet exact bulk material conveyor project requirements.

“Correct installation of suitable equipment ensures cost efficiency, optimum performance and safety, reduced risk of breakdown and extended service life of the conveyor system. The DustScrape dust filter system, which is used in conjunction with the contact-free AirScrape conveyor belt skirting system, provides an effective, energy-free dust emission prevention solution. The compact and lightweight system complies with most new dust prevention guidelines and prevents health and safety issues on-site. It also minimises product loss, by effectively preventing material from being blown into the surrounding environment.”

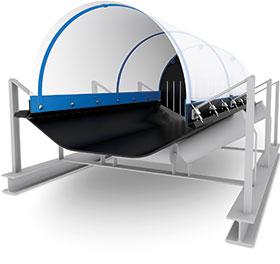

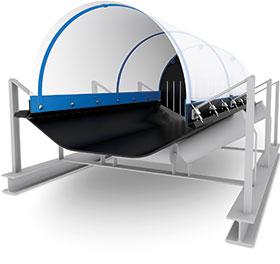

DustScrape consists of a durable filtering cloth that is installed above the conveyor belt, to retain dust particles, while remaining permeable to circulating air. This long-lasting filter cloth is available with different qualities for specific applications, e.g. grain transfer.

The DustScrape system comprises a filter cloth, support arches and skirts, arms to hold the system above the belt and a rubber curtain to eliminate further dust development – all sized to specific requirements. It is easy to install and can be retrofitted to existing conveyors for continuous or periodic operation.

Selection of the correct AirScrape size depends on the loading width of the conveyor belt and the required load-free zone of the belt edges. The AirScrape conveyor belt skirting system is installed above the load-free zone and generates the air-intake from outside, into the system. The generated airflow from above the conveyed material then gets filtered through the filter cloth, retaining any dust particles which are re-deposited back into the material flow.

For more information contact Ken Mouritzen, BLTWorld, +27 31 274 8270, [email protected], www.bltworld.com

Further reading:

Transporting substations for the world’s largest offshore wind farm

Motion Control & Drives

Dogger Bank Wind Farm will be the world’s largest offshore wind farm when it is completed. Mammoet was involved in providing transportation and weighing of the project’s three offshore substations.

Read more...

Lubrication application a key component for wire rope longevity

Motion Control & Drives

As part of its extensive work to help develop benchmarking standards for wire rope lubrication in South Africa, lubrication specialists Lubrication Engineers South Africa has found the Viper wire rope lubricator to be a key element for effective lubrication application and rope maintenance.

Read more...

Extreme pressure additives for oil

Wearcheck

Motion Control & Drives

Extreme pressure additives - the other metal guardians in your oil additives - work their magic under pressure.

Read more...

SEW EURODRIVE sets the pace with power packs in African mining

Motion Control & Drives

Comprehensively supporting the mining sector with commodity-specific drive train solutions, SEW-EURODRIVE has cemented its reputation as a trusted partner to the industry, a testament to its customer-centric approach.

Read more...

Anti-wear additives – the metal guardians in your oil

Wearcheck

Motion Control & Drives

Anti-wear additives are used to protect against wear and the loss of metal surfaces during mixed-film and boundary-film lubrication.

Read more...

SEW-EURODRIVE advances industrial performance with next-gen predictive maintenance

Motion Control & Drives

Predictive maintenance, once considered an emerging technology, is now a core requirement for modern operations and SEW-EURODRIVE is driving this evolution with its advanced DriveRadar IoT Suite.

Read more...

Generation surface drill rig

Motion Control & Drives

Epiroc is launching a new and improved PowerROC T45. This new generation surface drill rig offers increased fuel efficiency and high availability, and is a welcome addition to the PowerROC family.

Read more...

Coke drum integrity project at Canadian oil sands site

Motion Control & Drives

Mammoet supported a leading Canadian energy provider in Alberta’s oil sands with replacing its original eight coke drums.

Read more...

Polymer bearings contribute to heavy lifting success

Motion Control & Drives

Leading dock-levelling and materials-handling specialist, REV Designs & Installations designs and manufactures a wide range of loading, docking and lifting equipment including some of the largest scissor lifts ever produced in the country. A key engineering decision was to move away from greased steel bearings and fully adopt igus high-performance polymer bearings across the key pivot points of the new lifts.

Read more...

Press technology enhances performance and product quality at tissue machines

Valmet South Africa

Motion Control & Drives

Valmet has been selected to replace five existing tissue machine shoe presses with its state-of-the-art Advantage ViscoNip press technology for Lee & Man Paper Manufacturing in China.

Read more...