Technical experts frequently come across the metrological terms of calibration and verification. For some these two concepts are known and easy to differentiate, but these two terms can also cause confusion.

Verification made easy

According to the International Vocabulary of Metrology (VIM), the term verification is defined as: “Provision of objective evidence that a given item fulfils specified requirements.”

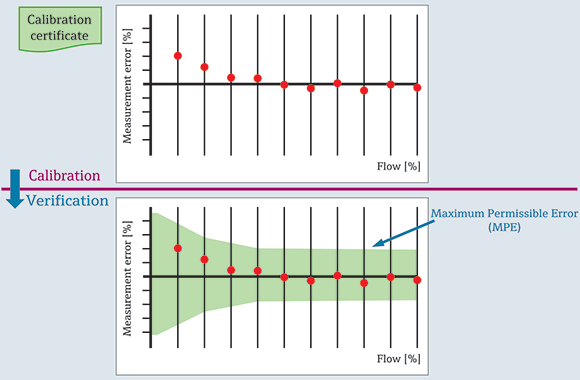

An interpretation of verification consists of checking calibration results as ‘objective evidence’ to comply with a ‘specified requirement’, such as the Maximum Permissible Error (MPE), defined either by a manufacturer, a legal metrology organisation or an end-user (i.e. process application). This situation is illustrated in Figure 1, where the device’s relative measurement errors obtained by the calibration rig turn out to be smaller than the MPE, meaning that the flowmeter (item) fulfils the specified requirement.

Endress+Hauser’s onsite Verification offerings:

Heartbeat verification

• Heartbeat Technology verifies the correct function of the measuring device according to the specifications and generates a protocol without process interruption.

• The automatically generated protocol supports the documentation requested by internal and external formalities, laws and standards.

Inline ultrasonic clamp-on verification

• The inline verification is a comparison of the results obtained from the unit under test (UUT) against the inline ultrasonic clamp-on flowmeter.

• A verification certificate which indicates the measured error between both the measurements is generated.

Calibration made easy

According to the VIM, calibration is a procedure to establish a relation between a quantity value given by a UUT and a reference quantity value (ref) obtained by a calibration rig, within its associated measurement uncertainty. The main objective is to check the accuracy of measurements by comparing the device in question with that of a known traceable reference. One fundamental requirement for carrying out a calibration is that the reference system must have traceability to the fundamental units of measurement needed to reproduce the unit flow.

Calibration of devices assists:

• The requirements of industry regulators and standards like FDA, IFS, ISO 9000 etc.

• To prevent influence of inaccurate measurements on the quality of the final product.

• To prevent energy or material losses due to improper control.

• To prevent safety issues caused by poor monitoring.

Endress+Hauser’s calibration offerings:

Onsite: portable rigs and buffer solutions

On-site calibration is performed by highly trained engineers. It is convenient and cost effective, and removes the need to send instruments offsite, keeping downtime to an absolute minimum. It also offers the highest flexibility as calibration can be scheduled according to process demands.

Laboratory

Laboratory calibration services are one-time or repeat contract-based calibrations of customer instrumentation carried out in a facility owned by Endress+Hauser. Calibration services performed in a laboratory have the advantages of the best calibration uncertainty and wide calibration ranges.

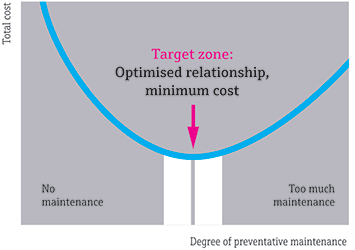

Calibration management service

Calibration management service is an optimisation service where Endress+Hauser take day-to-day management responsibility of a customer’s calibration function. Goals of this outsourcing are improving a customer’s plant operations, and securing calibration process compliance to internal and external regulations while reducing its costs.

For more information contact Preston Reddy, Endress+Hauser, +27 11 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved