End-user details

Name: Raymond Bosch

Designation: Electrical foreman cold stores

Company: Two a Day Group

Phone: +27 (0)21 859 7666

E-mail: [email protected]

SI details

Name: Willie Cameron

Designation: MD

Company: Software Services

Phone: +27 (0)21 851 4870

E-mail: [email protected]

Product details

Product name and version: Adroit version 8.2

Vendor: Adroit Technologies

Phone: +27 (0)11 658 8100

E-mail: [email protected]

URL: www.adroit.co.za

Application details

Location: Grabouw, Western Cape

Industry: Food & beverage

Project start date: 2016-02

Project end date: 2017-11

Application: Cold Storage management-RA/CA condition monitor/control

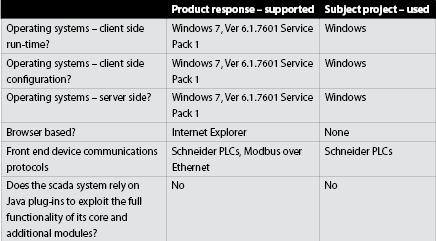

Server OS: Windows 7 Ver 6.1.7601, Service Pack 1

Client OS: Windows 7 Ver 6.1.7601, Service Pack 1

Application statistics

Tag count: 5 000 (Analog: 3128, Marshall: 589, String: 115, Digital: 99) Updates per day: 3931 tags every 5 seconds

Disk space for one day’s updates: 3 GB

Physical I/O count: Front End Devices 54 x 12766 Tags

Front ends: Schneider Electric - Modicon M340; Schneider Electric - Modicon Premium

Licences: Adroit 8.4

Scada configuration man-hours: 1000 hours

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

Adroit was installed in 1989 to monitor temperatures of the RA/CA rooms. To monitor the CO2 and O2 conditions, a sampling system was installed in 1990, the first controlling function added. Since 1992 additional functionality was added for controlling scrubbers, blowers and room setpoints. As the demand for cold storage grew, more tags were added. We started with 1500 and expanded to the existing 4252 of 5000 tags.

Two years ago it was decided to upgrade to Adroit 8 with a complete revamp of the mimics and animation. The refrigeration personnel is 100% dependent on Adroit for controlling the CA/RA stores, setpoints, sampling of gas conditions, reports and remote monitoring, so we needed to put in much more detail and animation, for visual monitoring.

In 2016, the logging of the tags was changed to SQL database for more flexible reporting and report generation for management. Version 8 was installed on a new machine and Raymond Bosch redid all the mimics in detail. All the control functions, which were controlled by 50 HMIs, were added to Adroit, with the support of 55 PLCs.

Q: What was the primary motivation for the project?

Using the more user-friendly version 8, we wanted to add more detail on mimics and rely on more control functionality.

Q: What were the main goals established for the project?

The goal was to give the existing refrigeration personnel more advanced technology to monitor and control the 134 cold rooms on the primary site, as well as 2 remote sites:

• To effectively control the recipes for optimum fruit quality.

• To optimise the loading/unloading of rooms.

• Energy efficiency – load shedding according to the recipe of the CA condition

Q: In the procurement decision-making process what were the primary considerations that influenced the product selection?

Local support and the ability to maintain the system internally.

Licensing, maintenance and support

Q: What licences have been purchased for this particular application?

Adroit 8.4.

Q: How is after-sales support handled on this application?

No agreement in place – support as and when required.

Q: Do you have a documented process in place to manage, test and install OS and scada system software patches?

No.

Integration, reporting and archiving

Q: Is the scada system integrated onto an intranet or the Internet?

No, it is a standalone system.

Q: Does the system include or interface with an expert system?

No.

Q: Is the system integrated with an MES/ ERP or other management reporting or control system?

No.

Q: Has any GIS (Geographic Information Systems) functionality been configured in the application?

No.

Q: Has any asset management functionality been configured in the application?

No.

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes, standard Adroit data logging and SQL.

Maintenance, reliability and asset optimisation

Q: Have any operational or production benchmarking tools been configured as part of the scada system?

No.

Q: What maintenance, reliability, asset optimisation or continuous improvement criteria were included in the user requirements specification for this project?

None.

Mobile device support

Q: Are you currently using tablets, mobile phones or other smart mobile devices to interact with the scada system? If so, for what purposes?

Yes – standby personnel plus technical support for refrigeration personnel.

Q: Do you allow users to interface with the scada system via their own personal smart devices? (BYOD)

Yes – certain privileged users for daily duties and standby use.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Local support and ease of use.

Q: What was the most significant change that you implemented in scada engineering practice/technology in this project?

To go paperless through the use of technology.

Q: What single operational feature most impresses you about the product now that it is in operation?

Electrical and mechanical debugging of the refrigeration system through forensic investigation.

Q: What impresses you most about the architecture?

Marshall agent uses 1 tag that can scan 16 bits.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

1000 hours.

Q: What tools were used to minimise the man-hours taken?

Excel importing and exporting tags.

Q: What human factors were taken into consideration as principles or development standards in the HMI design process?

Two a Day HMI Standard for skilled/unskilled operators.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Mostly standard Adroit libraries.

Q: How would you describe the library of graphic images?

Comprehensive.

Q: Did you use any ‘special’ images?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system alarms?

Adroit standard alarm management.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

UPS backup and fibre backbone with PLC safety routines.

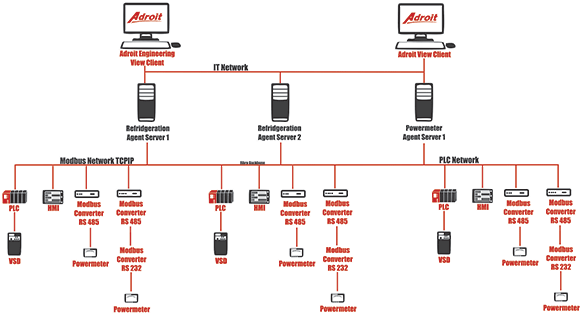

Q: What are the key physical communication layers and communication protocols employed in the system?

Power meters to scada: Modbus over Ethernet.

PLC to scada: Ethernet over fibre and copper.

PLC to VSD: CanOpen.

Q: What is the network speed and communications medium of the slowest link in this project’s scada network?

1000 Mbit/s over Ethernet.

Q: What is the network speed and communications medium of the fastest link in this project’s scada network?

1 Gbit/s over fibre.

Q: What levels of redundancy are incorporated in this scada application?

No redundancy as yet, scheduled for a 2018/2019 project.

Q: Was any specific custom code or scada scripting written for this project?

No.

Maintenance, reliability and asset optimisation

Q: What steps were taken to address maintenance, reliability, asset optimisation and/or continuous improvement aspects relating to this system?

Refrigeration personnel inputs and continuous modification as needed.

Security and data protection

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks (LAN, WAN, GAN, Internet, etc.)?

No.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

None, it is an isolated network with standard Windows security.

Q: What configuration backup and data archive backup methodologies have been adopted?

Remote use of Acronis/qnap backup system.

SI conclusion

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

Ease of debugging and satisfaction of the end user.

Q: What impresses you most about the architecture?

Open standards and the ability to upgrade.

Vendor responses

Product

Q: Vendor comments on product/modules?

Adroit 8.4.3 offers performance enhancements and Windows 10 compatibility.

Operating systems/VMware

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

Licensing is scanned I/O based – all internal logs are free, including alarms and historical log tags with databases. Base licence comprises of core modules.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Outright with technology support/maintenance agreement optional – the licence is a once-off purchase per major version release.

Q: What upgrade agreements are offered?

Group-wide support and sales arrangements are available along with maintenance agreements. Adroit minor version and patch upgrades are free.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

SLA (service level agreement), group-wide technology agreements, site auditing and onsite support can be offered as an annual agreement. Telephonic and remote desktop support is offered free during office hours.

Q: Do you have a documented process in place to manage and test OS patches and to release scada system software patches?

Yes, internally driven. The testing department has a procedure to test Adroit products against latest Windows releases and upgrades. Adroit has an audit procedure document.

Technology incorporated

Q: What new technology has been introduced into the product in the last 12 months?

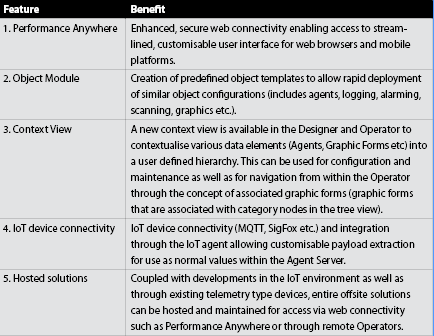

Performance Anywhere and the Adroit health monitor. In Adroit 10 we have added Object Module and Context View, OEE (overall equipment efficiency) Reports and Advanced Auditing Reports.

Integration and reporting

Q: What generic and/or product specific interfaces does the product have iro well-known MES packages?

OPC UA, OPC, .NET v4.0, VB v6.0, Excel, SQL Server and MS Reporting Services – the Adroit Smart Intelligence product is built on MS Business Intelligence technologies.

Q: What native historical data reporting options are available?

Our trends support export to Excel, PDF, JPG and CSV formats. Adroit has its standard flat file data logging that is used for trending and charts and can also log to multiple different databases Microsoft SQL, Oracle, etc. Adroit Scada interface can then also be used to create simple data queries to report data in the interface. Microsoft Reporting Services can then also be hosted in the user interface via the url tool. Adroit offers free report suite with Adroit audit reports.

Maintenance, reliability and asset optimisation

Q: What maintenance, reliability, asset optimisation and/or continuous improvement related modules or capabilities does the product incorporate?

SNMP capability – possible to monitor LAN performance and IT infrastructure. All software changes and processes are logged to Microsoft Windows Events with a unique ID for Adroit. Adroit can also log this data to SQL if need be. Adroit offers Report Suite which comes with free audit reports for the system.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

Adroit supports object-based generation of function blocks and scada objects in Mitsubishi Electric range of PLCs. I/O and PLC generated by Adroit.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

MS security and data and standard Windows security.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved