Automation projects are under cost pressure now more than ever. Time available from the final investment decision until start up is getting shorter because companies need to start generating revenue as early as possible. Contractors and project leads typically follow KPIs based on time savings and cost reduction within a project, while comparing them to previous similar project experiences. Last minute changes in projects are common, e.g. adding new devices or changing configurations after the final order is placed, so it is important to be flexible and take an agile approach to managing these situations wherever possible.

Smart commissioning is an efficient time-saving approach to commissioning intelligent devices via a fieldbus. By using smart DCS/PLC functions such as Device Templates, Pre-Configuration, and Remote and Bulk Configuration, engineers can commission faster and safer when compared to conventional onsite processes. The result is drastically reduced commissioning time, risk and effort.

Expertise is the key to fast, smooth and solid plant start-up

Commissioning is on the critical path for start-up, and since delays can cost millions, customers are constantly searching for new ways to be more efficient during this phase.

Assuming an average time of 1,5 hours per device, with conventional (device display, handheld or a service tool) commissioning, at a price of R1000/h in a medium size project with 2000 devices, this task will take 3000 hours and cost R3 million. Taking the same project, but using Device Templates combined with a streamlined commissioning processes, this task can be done in less than 500 hours and cost only R500 000.

Typically, the time-saving results in a 50-80% cost saving, mainly related to labour costs in larger projects with more than 200 devices and a good portion of intelligent devices. In addition, most work can be completed more efficiently due to early planning, reducing the likelihood of any impact on the project’s critical path. Moreover, this approach also avoids the risk of working on construction sites, as most of the work is done offline in safe office and workshop environments. All configuration and integration tasks are discussed and tested before the final commissioning of the devices, hence compatibility risks are eliminated.

With conventional commissioning, device diagnostics, like NAMUR NE107 and Heartbeat Technology, are sometimes not considered and therefore not configured, which often leads to false alarms in the DCS or Asset Management Systems. This often forces the customer to ‘switch off’ this functionality in the host system, which makes it impossible to utilise Heartbeat Technology and to adopt a preventive maintenance concept using sensor data as a source of information. To enable best practices, the optimum configuration of each device is mandatory.

The ‘smart’ factor is in the commissioning process

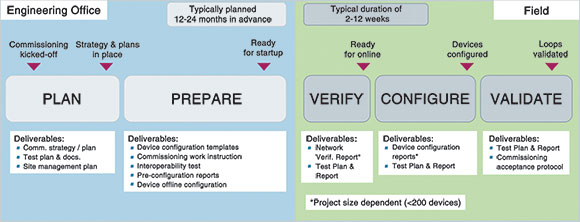

The essence of smart commissioning is to get involved as early as possible in the project discussions and make the best decisions at an early stage related to:

• Planning and preparing commissioning tasks in the engineering office.

• Efficiently performing commissioning in the field.

Figure 1 gives an overview of the two main phases as well as their associated deliverables.

Conclusion

Smart commissioning enables a faster and safer commissioning process and drastically reduces commissioning time, risk and effort. This value-added service is an integral part of Endress+Hauser’s extended service offering as it works to provide project consulting and execution services.

For more information contact Preston Reddy, Endress+Hauser, +27 (0)11 262 8080, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved