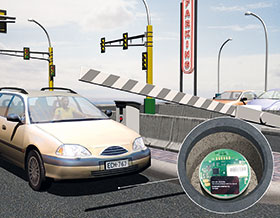

The ability to detect vehicles reliably offers significant advantages for asset management, resource allocation, site safety and traffic control. Identifying the right technology for a vehicle detection application can be challenging, and many factors must be taken into consideration, including task, size of target, sensing range, sensor mounting and whether the application is primarily indoor or outdoor. This article explains how a wireless magnetometer can be used for vehicle detection and describes the top three advantages of the technology.

What is a magnetometer?

Magnetometers can be either wired or wireless, but for the purposes of this article we will focus on wireless magnetometers, which offer important advantages to the end-user.

A magnetometer works by using a passive sensing technology to detect large ferrous objects such as trucks, automobiles, or rail cars by measuring the change in the ambient magnetic field. When a vehicle alters that magnetic field, the sensor detects those changes. As with other sensors, the range of the magnetometer will depend on the target.

Advantages of wireless magnetometers for vehicle detection

Cost-effective: A wireless magnetometer provides a cost-effective and convenient alternative to other sensing technologies. It requires no wiring or external control box, but achieves an accurate and repeatable response.

Minimally invasive: Wireless magnetometers are less invasive, less expensive and easier to commission quickly compared to inductive loops, because wireless magnetometer units are small, self-contained and don’t require extensive work under the concrete. The wireless M-Gage sensor from Banner, for example, can be installed above grade or below grade. Below-grade installation requires only a small 7,5 cm hole drilled into the concrete for each sensor location, which means less downtime for installation.

Low maintenance

A truly wireless magnetometer will not only offer wireless communication via radio, but will also be completely self-contained, including the battery. The long life of the battery ensures continuous performance for years at a time.

Important considerations

In order to detect reliably when the magnetic field is disrupted, a magnetometer must first be taught the typical ambient magnetic conditions. Therefore a vehicle must not be present when the sensor is being taught.

Another consideration when installing a magnetometer is that if the sensor moves out of alignment over time, it may cease to function properly. Because of this, a magnetometer must be rigidly fixed at the time of installation to ensure reliable long-term functioning.

Wireless magnetometers from Banner Engineering also feature an advanced algorithm that detects fluctuations and adjusts accordingly. Finally, in cold climates that experience large amounts of snow, it is often necessary to install the magnetometer below grade to avoid damage from snowploughs.

For more information contact Brandon Topham, RET Automation, +27 (0)11 453 2468, [email protected], www.retautomation.com

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved