Modern packaging plays an important role in preserving, protecting and selling a host of products, from items small enough to need tweezers to be picked up to those that need a forklift to be moved. Packaging also comes in a confusing array of materials, which can be costly if incorrectly selected or processed.

Countapulse Controls offers a broad range of opto-electronic sensors that have been developed to ensure packaging lines operate at peak efficiency for the packaging industry. Made by the respected German instrumentation manufacturer Leuze Electronic, the sensors are purpose-designed for the feeding, packing, dosing, detecting, labelling, sealing and other operations that go into the makeup of any packaged product.

Sensors for demanding requirements

Countapulse Controls' managing director, Gerry Bryant points out that the variety of materials used for packaging, as well as the surface properties and the specialised printing used in the industry require the highest standards of instrumentation and machinery.

"Modern, high-production packaging uses cutting edge technology, and sensors applied to these applications have to be capable of meeting the demanding requirements," he says.

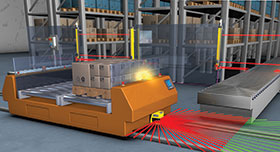

Leuze is one of the leading developers and manufacturers of opto-electronic systems, which use light in various spectra for sensing, monitoring and controlling products and equipment in the production line.

This includes standard opto-electronic sensors, colour sensors, label detectors and sensors for workplace safety. Also in the range are sensors for foil and glass detection, CCD sensors, forked photoelectric sensors and sensors for differentiating between glass and PET.

These can be effectively applied to hasten and improve quality control in any number of processes. In feeding and conveying, for instance, solid granules, loose goods, paste products, fluids or mixed items are transported, accumulated and passed on. Opto-electronic sensors are used to position products on conveyors, recognise their shapes, measure them for filling and sealing and even check the quality of printing and labelling.

"The many ways used to package products nowadays show the dynamics and bandwidth of the various packaging technologies. Leuze has expended considerable research and development effort in producing its range of opto-electronic sensors, using concepts aimed at improving speed, accuracy and performance in the packaging line," explains Bryant.

The complexity and depth of sensors available on the market can be confusing, and for this reason Countapulse Controls often assists customers to evaluate an application for either the fitment of new sensors or the retrofit of replacement units.

“While the Leuze sensor range is broad enough to offer units of the right type and size for virtually any operation in the line, we have found that in some instances we have sourced alternative sensor solutions for the customer,” concludes Bryant. “This is not unusual at all, and with the depth of expertise that resides within Countapulse Controls it is easy to apply best practice sensor technology to any application.”

For more information contact Gerry Bryant, Countapulse Controls, +27 (0)11 615 7556, [email protected], www.countapulse.co.za

| Tel: | +27 11 615 7556/7/8 |

| Email: | [email protected] |

| www: | www.countapulse.co.za |

| Articles: | More information and articles about Countapulse Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved