A critical component of farm operations, irrigation systems ensure regular water distribution to crops using a system of pumps, piping and sprayers. As water becomes a more scarce resource and affects operational costs, farmers must find more precise ways to manage agricultural irrigation systems to help conserve water supplies, while also operating more profitability.

On many farms, monitoring the irrigation system remains a manual chore. Workers travel throughout the many acres of the farm to perform manual checks on meters and then record and aggregate measurements to determine the status of operations. In some cases, farms do not have meters and rely on sight to decide if operations seem to be working correctly. As a result, farm operators cannot readily identify potential issues with pressures in spray nozzles that disperse chemicals over crops or an abnormally high electric current draw from pumps. The bottom line is: they do not even know how much water or chemicals are being used to feed crops. As agriculture is a large consumer of the earth’s freshwater supply, farmers must employ better management practices to operate their irrigation systems.

A SignalFire Remote Sensing System (SFRSS) gives farmers and water districts the ability to monitor and control different factors of the irrigation system from the convenience of a tablet, computer or even a mobile phone. Instead of travelling to multiple locations to collect data for analysis, the SFRSS can provide real-time status on water pressure, pump usage, pump water flow, water tank levels and other critical operating parameters. Using this data, farmers can analyse trends, determine smart irrigation based on weather conditions and calculate and analyse water usage and costs. An irrigation dashboard also supports more accurate planning of maintenance, based on equipment condition.

The SFRSS configuration

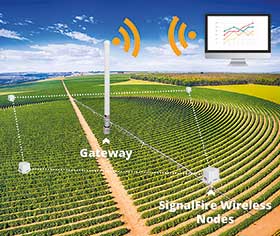

The SFRSS employs radio nodes to extract and transmit data from sensors to a gateway that serves as the central processing hub. Fuelled by built-in batteries or solar power, the nodes power the sensors for a truly wireless system. The gateway delivers the information to an off-the-shelf supervisory system using Modbus protocol over Ethernet.

Sensor agnostic, the SignalFire wireless telemetry system, allows farm operators to specify different sensor types to monitor an agricultural irrigation system. Farms can use pressure sensors to track pump and spray nozzle pressure, electric clamp-on current meters to measure the pump current, flowmeters to measure water and chemical usage and level sensors to monitor the levels of water storage tanks, all in one network.

Because the solution works as a mesh, nodes can hop over kilometres of distance, from one crop field to another, and back to a gateway located at the point of monitoring such as the headquarters of the irrigation district. An Ethernet interface module connects the gateway to a local area network, and a WiFi network, or a cellular modem, brings the information to the field operators.

In a farming environment, a wireless system must be able to spread over many square kilometres. The mesh network of the SFRSS permits many wireless devices to self-configure into a web-like structure over large areas regardless of hills, buildings and other structures. Robust gateways can accommodate hundreds of transceiver inputs from the multiple field sensors, enabling the network to cover a geographic range of a mega farm of 10 000 acres.

Using the SFRSS to monitor and control farm irrigation system operations, farmers can cost effectively:

• Use a broad range of sensors to assess different operating parameters.

• Broadcast information over long ranges.

• Download and integrate sensor data to a PLC within a control room.

• Conduct analytics to improve irrigation system operation and water efficiency.

• Reduce costs by operating with lower water supplies.

• Ensure compliance with regulations regarding water usage.

• Verify correct billing of water usage.

• Comply with environmental sustainability.

By implementing the SFRSS, farmers gain better control and visibility over the operations of their irrigation systems to save money while using water more responsibly.

For more information contact SignalFire Wireless Telemetry, +1 978 212 2868, [email protected], www.signal-fire.com

© Technews Publishing (Pty) Ltd | All Rights Reserved