In steam boiler systems, salts that have dissolved in the water lead to corrosion and deposits. To avoid this and depending on the operational mode and design of the steam generator, there are important requirements regarding the quality of the boiler feed water.

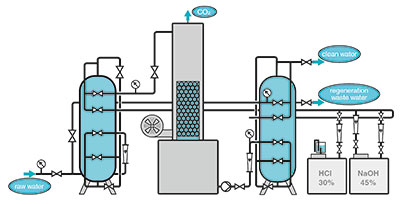

In a deionisation system, the salts that have dissolved in the water are removed using ion-exchange resins. These salts are dissociated, i.e. in positive cations and negative anions, and as a result, a so-called desalination line is set up as follows: cations exchanger – CO2 degasifier: anions exchanger – mixed-bed filter. Moreover, for the installation to operate properly, a regeneration station and neutralisation are required.

Construction and function of an ion exchanger

First, the water that is to be desalinated flows through the acid resin bed of the cations exchanger. Here, the cations (e.g. calcium (Ca2+), magnesium (Mg2+), sodium (Na+)) are replaced by H+ ions, which have been absorbed onto the resin. During this process, carbon dioxide, among other things, is produced.

CO2 degasifier: The free CO2 is dissolved in a secondary CO2 degasifier. Due to the expansion element, there is a high level of recirculation on the water‘s surface, and as a result, the gaseous CO2 is released. Fewer HCO3 ions are now generated, and therefore the secondary anions exchanger is discharged and the chemical and regeneration water consumption is lowered.

Anions exchanger: Here, the anions (e.g. hydrocarbonate (HCO3(-)), sulphate (SO42-) or chloride (Cl-) are replaced with hydroxide ions (OH-)), which have been adsorbed on the alkaline resin bed of the anions exchanger.

Mixed-bed filter: The secondary mixed-bed filter, also called a polisher, removes the residual ions from the water. It contains both highly acidic and highly alkaline ion-exchanger resins. By mixing the two resins, the residual ions can be completely removed.

Regeneration

When the ion-exchanger resins are completely depleted, they are regenerated. During this process, the acidic resin from the cations exchanger is flushed with hydro-chloric acid (HCl) and the alkaline resin from the anions exchanger is flushed with sodium hydroxide (NaOH). If there is still residual acid or alkali in the regeneration wastewater, it must be neutralised before it drains off into the sewage system.

So that pure water can be generated continuously, two desalination lines are required – one is in operation and the other is part of the regeneration phase.

Operational mode

The ion-exchanger resins are available as a suspended or fixed bed, or also as a combined suspended bed with a fixed bed section. Most commonly, regeneration takes place in counter current, i.e. charging occurs in one direction and regeneration occurs in the other. Generally, charging occurs from bottom to top and flushing occurs from top to bottom. Compared with the direct current method, a significantly higher product quality is achieved and fewer regeneration agents are consumed.

The GEMÜ solution

To dose acids and alkalis, and to distribute the water, the GEMÜ R690 and R677 diaphragm valves are used, which have nominal sizes of DN20 – DN50, EPDM as diaphragm material and a GEMÜ 805 variable area flowmeter. The valves are also equipped with GEMÜ 1235 electrical position indicators.

For more information contact GEMÜ Valves Africa, +27 (0)11 462 7795, [email protected], www.gemue.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved