Replacing original sensing, measuring and monitoring devices represents the ideal opportunity to assess a specific application and the suitability of the equipment. This is according to Gerry Bryant, managing director of Countapulse Controls, who adds that often a better fit for purpose solution which incorporates new technology is available.

Frequently, the selection of the original sensing devices occurred with one particular machine, rather than the entire process, in mind. Bryant explains that when replacing the original sensors, it is possible to achieve a more holistic overview of the process.

“By involving a specialist sensor supplier in the process, it is often possible to provide a more cost efficient and plant related solution, and this can end up providing significant savings for an operation,” says Bryant.

As sensing and measuring technology continues to develop, all industries have to adapt. Bryant says that Countapulse Controls has evolved from being a supplier of sensing and monitoring devices to a solutions provider offering advanced technology packages that incorporate high level support.

This is underpinned by assistance in both the selection of application appropriate and cost effective solutions, as well as the installation of total systems.

“When assessing a customer’s application, it is best to look beyond a single problem area,” says Bryant. “A more structured approach is required to obtain a general overview of the specific requirements. And by considering the overall operation of the plant, we are able to provide a solution that encompasses any unforeseen needs within the process.”

Bryant cautions that selecting sensors is not as simple as matching a model number to a requirement. There is the need to assess the operating environment and gain a comprehensive understanding of the elements that need to be monitored, and only then can a fit-for-purpose sensing solution be applied.

Parameters that need to be taken into account include the range of the sensor, the speed of the automatic process, the background conditions and type of product, auxiliary equipment and the circuits within the process.

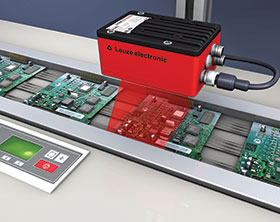

An example would be selecting a photo electric sensor that is suitable for various switching distances within a plant. The customer would have the option of standardising on one sensor type, as opposed to having different devices throughout the process, and this would reduce parts inventory and associated operating costs.

A failure to understand the full capabilities of a specific device could result in the selection of a far costlier sensor, when a more cost effective option would suffice in a particular application.

“Technical acumen and experience play a large role in reducing the effects of human error, which could result from uninformed product choice and the absence of appropriate technical information,” he says. “This is where a dedicated technology and solutions provider plays a vital role. Each application has unique, specific needs. In order to provide a balanced solutions driven approach, it is advisable to select a supplier with extensive industry knowledge and a diverse portfolio of customers.”

Countapulse Controls is able to provide its local customers with the latest technology and innovations being introduced into major international markets such as Europe.

“By maintaining excellent relationships with our principals, in addition to an intimate understanding of the local market, we are able to identify those products that are most suited to the southern African context,” concludes Bryant. “This differentiates us from online suppliers that are merely selling boxes, as opposed to application specific solutions.”

For more information contact Gerry Bryant, Countapulse Controls, +27 (0)11 615 7556, [email protected], www.countapulse.co.za

| Tel: | +27 11 615 7556/7/8 |

| Email: | [email protected] |

| www: | www.countapulse.co.za |

| Articles: | More information and articles about Countapulse Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved