South Africa’s largest municipal water utility manages the delivery of potable water to a large geographical area of around five million people. It is also responsible for the running of wastewater treatment plants in and around the Johannesburg area.

Background

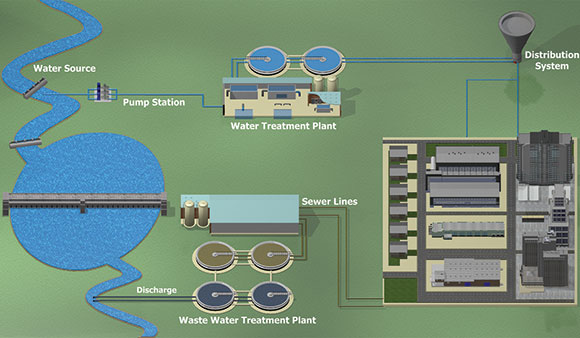

In order to comprehend the challenges facing a water utility, a thorough understanding of the functioning of a water system, is necessary. Such a system is made up of three distinct parts: water treatment, water distribution and wastewater treatment.

The distribution of potable water, delivering it to the city with the appropriate quality, quantity and pressure, comprises reservoirs (bulk storage from the water treatment plants), pump stations, towers (to regulate availability and pressure) and a network of pipes. This is by far the most complex and difficult of the three parts of the water system. The success of water distribution and overcoming the challenges determines the success of a water utility.

Operational challenges

The following are working challenges that the water utility experiences daily:

1. The political commitments to its people.

2. Unplanned outages from overloaded infrastructure (limited redundancy).

3. An ageing distribution pipe network; there is a daily movement of approximately 1,5 mega litres of water per day.

4. An ageing pumping and piping network asset base.

5. Rapid growth in demand and geographic expansion in a fairly mountainous area.

6. Constrained capital investment for refurbishment.

7. Higher cost to maintain compounded by poor preventative maintenance practices.

8. Unavailability of qualified and experienced resources.

9. National scarcity of water; water availability in South Africa varies greatly.

10. Increasing costs of energy.

Therefore, easy access to data and reporting is essential to management. The biggest challenge facing distribution for this water utility is that it is made up of lots of distribution elements.

Infrastructure

The infrastructure assets that support the business of the utility are important and cannot be underestimated. This is comprised of:

• 89 water reservoirs.

• 28 water towers.

• 4 laboratories.

• 12 581 km of distribution pipes.

• 6 wastewater treatment works.

This utility supplies 1,4 million domestic, commercial and industrial customers and serves an estimated consumer base of 5 million people with approximately 1 574 Ml/day of potable water. It employs approximately 2500 people and services an area of approximately 1600 square kilometres.

The problem

During a risk assessment, the water utility recognised the potential value of a well organised telemetry and scada system. This vision of a data driven decision-making strategy received the full backing of the water utility and the city.

This was a turning point. It transformed the water utility from being led by consultants to actively engaging with consultants and suppliers to develop its own vision and dream of being a leading African city in water distribution.

The solution

In order to achieve this vision, the water utility chose two South African technology partners who shared the vision: Adroit Technologies, the developers of the Adroit SCADA system, and Specialist Systems Engineering (SSE), responsible for the telemetry hardware and network.

A specification driven approach was taken. After consultation with all internal stakeholders, a set of standards were drawn up, in conjunction with Adroit Technologies. These are still being modified and developed today. The benefits of this approach have helped the water utility operations ensure quality of supply from any number of service providers. In addition, the standards not only look at the way the system will be engineered, but how the engineering will be implemented to support a knowledge driven solution.

In summary

The solution is a very effective management tool because it facilitates this water utility to use its data proactively by providing early warnings of system failures and conditions. As a result, management is able to detect problems such as leaks before its customers – the public – report the fault. They can then make informed decisions about the replacement of various assets in the field.

Adroit Technologies implemented a reporting system that delivers critical information to the various managers on a daily, weekly and monthly basis, including level control, pumping pressure and telemetry system uptime. The Alarm Management and Analysis product was also added. This allows the technical management team to identify and manage the network, as well as to start looking at worst performing assets and do an asset life-cycle management from a more knowledge driven point of view.

It is a reliable and cost-effective level control and monitoring solution for this water utility. It efficiently provides information on the status of control and monitoring networks for operators to make the right decisions.

The water utility is continuously working with industry leaders and scouting for enhancements in sensor technology. The more refined the sensors are the more refined their predictions will be – therefore, it is important to keep abreast of technology.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved