Double digit increases in the cost of electricity since 2006 have eaten into corporate and industry profitability and was listed by Business Times as a contributing factor in the decline in business confidence in 2016.

Using the Internet of Things (IoT) technology can deliver efficiencies and cost savings that can, to a large degree, offset the profit-eroding impact of continued price escalation.

“In the wake of rapid price increases companies have initiated a number of projects to improve energy efficiencies with some success. Implementing an IoT strategy can be the differentiator,” says André Strauss, director of partnerships at Pretoria-based technology company IoT.nxt.

“Some executives are hesitant to introduce IoT solutions because of the perceived cost of additional capital expenditure. This is not required. The implementation of IoT strategies gives companies crucial insight into power usage, which allows them to manage their tariff range in real time. Having insight and control over their tariff range thresholds and consumption, turns this profit-drain into informed decisions with real-time benefits,” he adds.

The website European Energy Innovation reported late last year that the IoT can bring significant benefits for energy efficiency. “At the level of the production of energy, smart grid sensors can improve utility operations and performance by better monitoring the energy network, so that resources are allocated more precisely and closer to the actual demand needs, avoiding energy waste. At the level of consumption, smart meters can provide a wealth of information to help minimise energy costs, e.g. through fully automated billing based on time of use or network status, or enabling meter-to-appliance communications to help consumers change their behaviour to reduce their costs,” according to a report on the site by Mário Campolargo, director for the Net Futures department of the European Commission.

Strauss lists seven benefits of energy consumption and monitoring:

• Information gathered provides a 360 degree view of where energy is lost, misused or even stolen.

• Energy load and disturbance management to detect problems before they happen.

• It creates organisational awareness about energy management.

• Facility managers can use the information to optimise energy without wasting spend.

• Information about energy utilisation over a period of time proves valuable insight for an alternative energy strategy.

• Effective carbon footprint management to conserve energy as well as the environment.

• Cost reduction so companies can save money and energy.

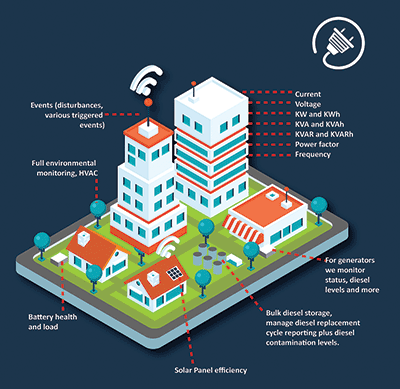

“The IoT.nxt Raptor edge gateway integrates monitoring capability to monitor far more than the traditional elements of energy processes and assets. This allows a company to monitor every variable in its operational chain, providing a comprehensive real-time, situational context of every element in its energy landscape. The Raptor was designed with interoperability in mind,” explains Strauss.

IoT.nxt is in the final stages of developing this application for a large regional shopping mall in Gauteng, where energy charges are a key cost factor. “Lighting and air conditioning contribute the biggest percentage of the total energy cost at this mall. Once installed our solution will bring costs down significantly,” he adds.

At large manufacturing plants, mining, utilities management by cities, and several other industries, the energy efficiency solution could be integrated into a larger IoT project where different elements are managed better through real-time monitoring, delivering even greater costs savings.

For more information contact Daleen van Wyk, IoT.nxt, +27 (0)83 302 0827, [email protected], www.iotnxt.com

© Technews Publishing (Pty) Ltd | All Rights Reserved