Yokogawa Electric Corporation has announced that its subsidiary, Yokogawa Solution Service Corporation, has completed the installation of a software-defined networking (SDN) solution at four paper plants in Japan that are operated by the Oji Group. This is the first plant-wide implementation in Japan (based on a March 2017 Yokogawa market survey) of SDN, a software-based technology that enables the creation of virtual network environments. As part of this undertaking, Yokogawa assessed the company’s IT infrastructure, including its existing networks, and designed and deployed SDN-based networks at these facilities.

Flexible implementation of virtual networks

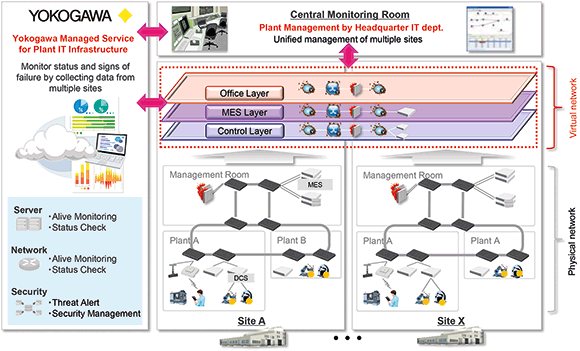

With conventional plant networks, security devices (i.e., routers, firewalls) must be installed and configured for each individual application, location and facility. The software-based SDN technology enables flexible implementation of virtual networks for each individual application, linking network devices using the same physical network. This facilitates the integrated management, implementation and reconfiguration of networks. Also, it helps to reduce the required number of network devices and the amount of wiring that needs to be installed, saving both operating and management costs. Furthermore, the visualisation of network status leads to enhanced security. Problems can be easily identified and network operators can remotely shut down specific segments of the plant network in the event of an emergency.

Yokogawa won this order because the customer highly valued its solid track record in delivering production control systems, wealth of production site knowledge and experience in providing solutions that lead to enhanced productivity, safety, and product quality.

For this project, Yokogawa chose to use a proven SDN network device solution, NEC Corporation’s Univerge PF series of controllers and switches. While minimising impact on plant operations is usually difficult when replacing IT infrastructure, Yokogawa was able to do this by leveraging its abundant experience and knowledge of production sites. At each of this customer’s plants, Yokogawa assessed the IT infrastructure, including existing networks, and based on this assessment then designed and deployed its SDN technology solution.

Security management service

Yokogawa is also providing, on a trial basis, a security management service that monitors the status and health of the networks throughout these plants. While enabling timely preventive measures that help to maintain the health of the networks in these plants, this service also ensures that prompt actions can be taken in the event of an emergency.

In plants around the world, there is an increasing need to improve productivity, safety, and maintenance efficiency, and this is being achieved through the introduction of IIoT technology. Networks help to create new value by connecting various types of devices, but it is essential to be able to change their configuration, quickly respond to surges in data volume, and ensure more secure operations. For the optimal implementation of IIoT technology, attention is now increasingly turning to the use of SDN systems in plant IT infrastructure. This will also help company IT departments manage the infrastructure at their plants in a more integrated manner.

Capitalising on its production site know-how, Yokogawa will continue in its endeavours to introduce SDN and other cutting-edge technologies that will enable the realisation of smarter plant IT infrastructure.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved