The selection process for bidirectional and wide range flow metering can be limited by both application requirements and the physical design constraints of the flowmeter itself. Using proven concepts, ABB Compact DP flowmeters can be deployed to offer reliable solutions to these unconventional applications.

Bidirectional flow

The need to measure flow rates within the same flow loop in opposite directions can be accomplished in two ways:

•Employ two meters with each having a different flow direction (vortex/swirl meter, orifice plate, turbine meter and Pitot tube).

•Install one meter capable of bidirectional flow by design. (Coriolis meter, wedge meter, Pitot tube, magnetic flowmeter).

With the employment of two distinct meters, the disadvantages of additional hardware costs, meter installation requirements (piping lengths), and the complexity of signal switching needs must be considered. The maintenance aspect alone, which is sometimes neglected, is an important factor when considering the total cost of operation. By using a meter that has been designed with bidirectional capabilities, cost aspects of procurement, operation and maintenance can be greatly reduced. Within the differential pressure flow meters category, technology advancements have been made that now allow easy setup of bidirectional signal processing within the pressure secondary itself.

Certain ABB Compact DP flowmeters take advantage of technologies that allow bidirectional flow to occur within one measurement device. Figure 1 depicts a typical compact wedge flowmeter showing the concept of its restriction in a symmetrical relationship to its pressure measurement ports. This allows one flowmeter to be used in both the forward and reverse flow directions.

ABB’s Torbar Pitot tube is also capable of two-way flow measurement when suitably configured. When coupled to a DP secondary, these flowmeters can employ a split range output signal scheme that allows the receiving equipment (PLC, DCS etc.) to determine the flow direction and rate.

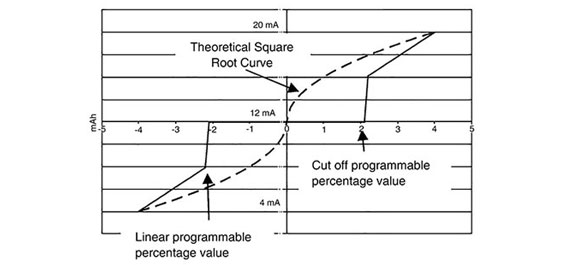

Under this arrangement, the zero flow point is established based on the range of forward and reverse flow (Figure 2).

For equal flow rates this becomes 12 mA or 50% of the normal 4-20 mA full scale electrical output. The flow direction is then indicative of the output value (4-12 mA = reverse/12- 20 mA = forward) while the flow value is determined by the absolute value of the DP reading. For unequal ranges the 'zero flow point' is a calculated value based on the DP reading of each flow direction. By employing these techniques, operators have the ability to monitor both the flow rate and direction while keeping installed equipment to a minimum.

Dual-range (stacked) flow systems

Many flow metering devices are susceptible to reduced performance at low flow rates or as commonly expressed – high turn down ratios. This can be especially true for differential pressure flowmeters, but can be easily overcome when other technologies having expanded capabilities are not suitable for a particular application.

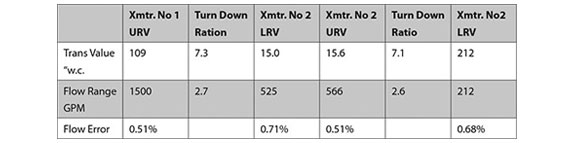

Stacking involves two or more transmitters coupled to a single flow device, each having a different flow range, and continuous monitoring of all signals. At a predetermined set point, the flow reading will switch from one transmitter to the other, using a simple algorithm in the PLC, DCS or computing device. This change over point is optimised to achieve the best performance possible from each transmitter as seen in the example below. Here the table shows the value of DP vs. flow rate at the point of Upper Range Value (span setting) and Lower Range Value (low end cut-off) for each transmitter and the expected flow system error assuming an ABB wedge meter as the primary device.

Had this application used only a single transmitter to cover the full flow range, the expected flow error at the LRV of 212 GPM would be in excess of 3.3%.

This same principle can be applied to all ABB Primary DP flow solutions and is able to be enhanced further when using multivariable transmitters for compensation of compressible fluid flow (gas or vapour).

For more information contact ABB South Africa, +27 (0)10 202 5000, [email protected], www.abb.com/flow

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved