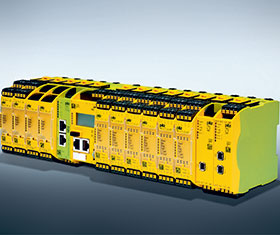

In the quest for higher performance and simpler project management, Pilz has added new base unit PNOZ m B1 to its range of configurable control systems PNOZmulti 2. Not only does it offer higher performance for machines with a larger function range, i.e. for larger projects, but it also provides a connection to all common fieldbus systems via the corresponding expansion modules.

For the first time, the new base unit PNOZ m B1 contains no inputs or outputs: expansion modules are used to adapt the system to the application. Two integrated Ethernet interfaces save costs, as there is no need to connect an ETH expansion module. The number of expansion modules that can be connected on the right-hand side has been increased to eight on the new base unit. Short downtimes and high plant availability are guaranteed by connection to common fieldbus systems via the respective expansion modules.

Project management made simple

The maximum program size of the PNOZ m B1 has been quadrupled: up to 1024 connections can now be inserted between the elements. Projects can be stored on a USB memory stick. The pluggable USB data medium allows several projects to be stored and enables machine-specific management. One of the programs can be selected to run via the Project Manager. It is also now possible to set the date and time for PNOZ m B1 in the PNOZmulti Configurator. And an illuminated display helps to provide convenient on-site diagnostics. PNOZ m B1 can be used from Version 10 of the software tool PNOZmulti Configurator.

Field connection guaranteed

The configurable control system PNOZmulti 2 can now also be connected to the fieldbus system CC-Link, in addition to Profinet, Profibus, Ethernet/IP and many more. If PNOZmulti 2 is to be connected to another fieldbus system, this can be achieved without having to change the program: that’s because one fieldbus module can simply be swapped for another.

Open for safety

The system is an open, configurable control system for safety functions, which can be used flexibly and industry-wide for safety and automation, independently of the higher-level plant control system. Use of the available expansion modules allows finer granularity, enabling the control structure to be adapted precisely to the application. Users only purchase what they will actually use, saving time and costs.

Setting safety standards

The configurable control systems are particularly suitable for implementing multiple safety functions on plant or machinery. The system is modular and expandable, so it can grow with the machine as it expands or as its requirements change. PNOZmulti 2 can be connected to common communication networks. The safety architecture can be created independently of the higher-level operational control system, because its application is independent of the machine or plant type, country or industry. That is how users standardise their safety.

For more information contact Craig Cuff, Prime Automation, +27 (0)41 819 7746, [email protected], www.primeautomation.co.za

| Tel: | +27 41 819 7746 |

| Email: | [email protected] |

| www: | www.primeautomation.co.za |

| Articles: | More information and articles about Prime Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved