The mining environment presents some of the harshest working conditions, from extreme temperatures to dust, wind, rain, floods and exposure to sunlight. However, with mobile machines and vehicles playing such a crucial role within the industry, they must be able to withstand these arduous conditions while also performing to the highest operational and safety standards.

While it may seem simple enough, the critical machinery that is responsible for the productivity of operations functioning within these environments requires technology that promotes efficiency, productivity and safety, especially with the industry facing increased cost pressure from the global slowdown in demand for commodities.

In order to achieve this, 3D sensors can be employed to provide area surveillance, edge recognition, line guidance, collision avoidance, distance monitoring, object recognition and reflector tracking – a step towards achieving safer and more efficient workplaces. Only with the right sensing technology in place though, can mining and maintenance managers hope to maximise their production, efficiency and safety in the long-term.

The dangers of poor detection

In the past, traditional methods of detecting vehicles, areas and objects involved the use of line scanners that would often result in motion blurs and ultimately inaccurate readings. In the mining industry, this creates risks to both worker safety and on-site productivity, something that business simply cannot afford.

Detection of both scenes and objects is vital at a mining site in order to prevent vehicle collisions, worker injuries and to ensure that the use of time and space are both optimised.

The solution

ifm’s O3M 3D sensor is the first of its kind with patented PMD technology forming the basis for a sensor system that can cope with the harsh operating conditions of mobile machines.

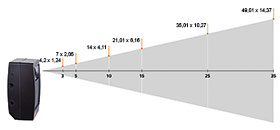

How it works – the function principle of the PMD technology is based on time of flight which ensures detection of scenes and objects with just one image capture in three dimensions, and without motion blur. The scene is illuminated by modulated, invisible infrared light and the reflection hits the PMD sensor. Each pixel on the PMD chip determines the distances to the scene from the phase shift between the transmitted and received signals.

Robust and compact – the sensor system is specially designed for outdoor applications and changing conditions including wind, rain and varying levels of sunlight. It also has a high operating ambient temperature range of -40 to 85°C.

No moving components – the sensor does not incorporate any moving components, making it perfectly suited for mobile machinery as well as particularly robust and wear free.

Reliable and fast – a highly developed algorithm from the automotive sector, and a frame rate of up to 50 frames per second, allows the sensor to generate fast and reliable calculations of 3D information.

Whether it is to prevent vehicle collisions, worker injuries, provide edge recognition, area detection in drill rigs or object detection and line guidance, ifm’s new O3M 3D sensor is tailored to meet the demands of harsh applications in the mining industry.

For more information contact ifm electronic SA, 086 143 6772, [email protected], www.ifm.com/za

| Tel: | +27 12 450 0400 |

| Email: | [email protected] |

| www: | www.ifm.com/za |

| Articles: | More information and articles about ifm - South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved