Valves switch up to four times faster

October 2015

Valves, Actuators & Pump Control

Pneumatic positioners match the particular current valve setting with the set-point signal as a control value. The control air, as the input quantity, generally corresponds to a unit signal of 0,2 to 1 bar. Positioners are also volume boosters which convert the control air at a minimal pressure to a proportional, high control pressure for the positioning of the valve.

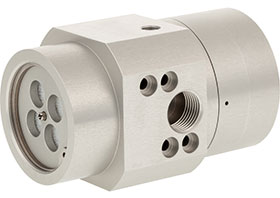

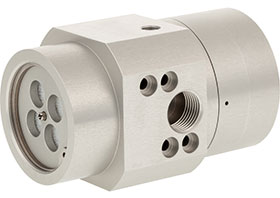

However, control valves with large volume, pneumatically-operated, part-turn and piston actuators, usually need several seconds for large positioning processes or to close or open fully. Concerning valves from DN 150 upwards, this can often result in restrictions in control quality. Now, with the newly developed, high precision 4090 pneumatic volume booster from Schubert & Salzer Control Systems, it is possible to amplify the air strength of the set-point signal from positioner to actuator such that these control valves – depending on nominal valve size – operate up to four times faster without any further modification.

Pneumatic volume booster

The pneumatic volume booster is based on a diaphragm system with which the pressure and volumetric flow of the control air are increased up to 6 bar through the controlled insertion of supply air. In the volume booster, the control air is fed through an adjustable bypass to the actuator. By controlling the flow rate in the bypass, the switching threshold for activating the amplifying air can be controlled precisely. This ensures that the pneumatic volume booster applies the default amount of supply air to the actuator with small changes in pressure, i.e. small control interventions. When the adjustable bypass pressure threshold is exceeded, the pneumatic volume booster is activated and releases the additional pressure amplification for the control air so that the adjustment of the valve stroke or, respectively, the part-turn actuator is substantially faster.

In the venting also of the actuator, the pneumatic volume booster adopts the same function and makes a vent valve operate when the supply air pressure is reduced. An exhaust air filter fitted here minimises sound emission.

The 4090 pneumatic volume booster enables significant reductions in switching times both in the closing as well as the opening of a valve. Using a DN 300 ball sector valve for a direct comparison, the closing time for a single-acting actuator falls from 43 seconds to 21.5 seconds with a standard setting and to just 10 seconds with an “aggressive” bypass setting on the booster. This new pneumatic volume booster not only shortens switching times significantly but also optimises the control quality particularly for control valves in the larger nominal sizes.

The volume booster can also be connected retroactively with ease to G 1/4” inline linear actuators and to part-turn actuators with a Namur (1/4”) interface.

For more information contact Keith Hedges, Macsteel Fluid Control, +27 (0)82 575 9354, [email protected], www.macsteel.co.za

Further reading:

Duplex valve improves continuous production at Gauteng manufacturing facility

Valves, Actuators & Pump Control

In a recent installation at a Gauteng-based manufacturer of household and personal care products, Allmech provided a tailored water treatment solution to ensure a consistent supply of soft water for steam generation, an essential element in the client’s 24/7 production cycle.

Read more...

Developing solutions for SA’s wastewater challenges

Valves, Actuators & Pump Control

KSB Pumps has a proud global legacy in the development of self-priming pump technology, which reflects decades of engineering innovation and application expertise. Building on this foundation, KSB’s AU series has extended the company’s self-priming expertise into screened wastewater handling, which meets the growing needs of municipal and industrial sectors worldwide.

Read more...

Helping to solve wastewater challenges

Valves, Actuators & Pump Control

KSB Pumps and Valves is doubling its efforts to help government and municipalities find practical and technical solutions to the growing wastewater challenges gripping large parts of the country.

Read more...

Ultra-durable stainless steel submersible pumps

Valves, Actuators & Pump Control

KSB Pumps and Valves has launched a rugged stainless-steel submersible pump range designed for deep borehole use and other demanding freshwater and saline pumping applications.

Read more...

Industrial valve solutions

Bearing Man Group t/a BMG

Valves, Actuators & Pump Control

BMG’s Fluid Technology division supplies and supports an extensive range of components for fluid technology systems. These include valves, hydraulic hoses and fittings, accumulators, cylinders, heat exchangers, hydraulic motors and hydraulic plumbing, as well as pumps and reservoir accessories.

Read more...

New wastewater pump for local municipalities and industries

Valves, Actuators & Pump Control

The latest wastewater pump from KSB Pumps and Valves is making waves in the industry due to a host of new features that provide users with an ultra-durable long service pump with fewer blockages and a lower maintenance requirement than traditional pumps.

Read more...

The critical role of check valves in fluid systems

Valves, Actuators & Pump Control

In fluid power systems, the performance and reliability of the entire operation often hinge on components that are small in size but significant in function. Among these, the check valve stands out as a fundamental yet frequently overlooked element.

Read more...

ENERGYValves expands operations

Valves, Actuators & Pump Control

ENERGYValves is expanding its operations with a new facility in Cape Town. The new premises will significantly enhance the company’s capacity to serve the Cape Town market and surrounding areas.

Read more...

Pumps lead the way with advanced technology

Valves, Actuators & Pump Control

The KSB GIW MDX pump has consistently represented a major leap forward in mill duty applications, with KSB relying on customer feedback to improving the design continuously.

Read more...

Wireless leak detection valve

Valves, Actuators & Pump Control

Designed to prevent water leakage by automatically shutting off the water supply when a leak is detected, the Runxin F104 wireless leak detection valve is one of the latest offerings from Allmech.

Read more...