Veolia Water Solutions & Technology (Veolia) is a world leader in engineering, building and managing water treatment plants. It has designed the technological solutions used at these plants and also offers a whole range of associated services to ensure the day-to-day technical efficiency and durability of all solutions installed on its customers’ sites.

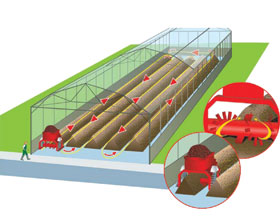

Solar sludge drying process

In the solar sludge drying process, sludge is treated by a centrifuge and laid out in a greenhouse heated by solar radiation. An automated robotic turner is used to aerate the sludge and accelerate water evaporation. The robots are radio-controlled, which provides a more robust solution than the traditional wired approach. With wireless control of the robots, the entire operation is automated, and there is no further need for operators to enter the greenhouse.

Radios are attached to the robots to enable information to be sent back and forth to the control station. This means the operator can control the robot remotely, program its movements and know its current position. The robot has an onboard controller, which interfaces with the radio. “Implementation proved to be very simple, thanks in particular to ProSoft Technology’s technical support,” explains Veolia’s Xavier Bousquet. “Our major concern was reliability. We had to have a reliable solution, with none of our users encountering any problems. This is indeed the case with ProSoft Technology’s RadioLinx solution.”

A reliable transmission system

RadioLinx solution from ProSoft Technology brings all the advantages of wireless connection to industrial automation applications, while still offering high levels of reliability. In addition to its ability to withstand harsh operating conditions, it also improves the transmission of Ethernet data packets. The standards set out in IEEE 802.11 (commonly known as WiFi) bring an extremely high level of security (802.11i), flexibility and interoperability to industrial automation applications. Originally designed for office and home applications, these less robust technologies have limitations when it comes to industrial protocol transfer, resulting in transmission problems for industrial automation systems associated with the radio transmission method used for Ethernet packets. But the RadioLinx range of industrial solutions ensures optimal transfer of data packets. To improve data packet transfer, RadioLinx uses a specific signal processing algorithm implemented by ProSoft Technology, which allows better use of the full bandwidth and supports the fast data transmission speeds demanded by industrial automation engineers. This is vital for industrial applications (involving protocols such as EtherNet/IP) with a need to transport non-critical messaging data, but also critical industrial I/O data.

With its Power over Ethernet specification, the power supply and connection of the radio system to the wired Ethernet is done via a single cable (instead of two), which greatly simplifies installation and reduces set-up times. Another valuable function of the RadioLinx series for this installation is that it supports serial encapsulation, which means that serial peripherals can be used and integrated into the main Ethernet architecture of the control system. The radio used in this application ensures high performance for both 2,4 GHz and 5 GHz band configurations.

For more information contact Bob Petrie, Throughput Technologies, +27 (0)11 705 2497, [email protected], www.throughput.co.za

| Tel: | +27 11 705 2497 |

| Email: | [email protected] |

| www: | www.throughput.co.za |

| Articles: | More information and articles about Throughput Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved