Manufacturers today require a high degree of certainty and confidence to achieve timely production, as well as the flexibility to make changes in product and material specifications as and when required. This enables them to respond to the intense global competition and major market shifts.

To address today’s market demands and in keeping with its future business direction, Yokogawa has added several significant new capabilities to its flagship DCS Centum VP Release 6 (R6). This is the platform for delivering four new innovations: Hyper-intuitive Operation; Total Automation Management; Intelligent Plant Conductor; and Sustainable Plant Operation.

Each innovation addresses strategic challenges faced by today’s plant owners as they strive for greater operational integrity. Yokogawa has emphasised its objective to leverage two enabling technologies in this development programme namely: field digital technology and dynamic process simulation.

The adaptive evolution of Centum VP R6’s version 01, focuses on addressing the customers’ need to keep up with the fast pace of change in the business landscape and technology, while delivering maximum return on assets and the lowest total cost of ownership. Centum VP R6.01 brings together smart engineering, advanced operation, system agility and a sustainable plant.

Featuring an exciting expansion of Yokogawa’s line-up of I/O devices, it introduces crucial new control system components. Combined with an intuitive engineering environment, it dramatically reduces the time required to configure and install a control system.

New features of Centum VP R6.01

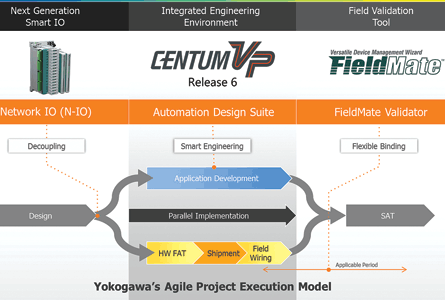

1. N-IO (Network-IO): The N-IO is a new field I/O device that fulfils the functions of universal I/O and a signal conditioner, enabling configurable software and flexible I/O assignment. It has an I/O module that accommodates multiple signal types, accepts up to 16 points, and allows specification of an individual signal type for each point. With the N-IO, it is no longer necessary to replace the I/O module, reducing the amount of rewiring that must be done when changing sensor types and/or layouts during a plant revamp. This significantly reduces the amount of work that has to be performed by plant engineers and maintenance personnel.

2. Automation Design Suite (AD Suite): The AD Suite is an integrated platform that ingenuously facilitates project execution, system integration, and site execution, bringing certainty and confidence through all project phases and the start-up, operation, maintenance, expansion/upgrade, and extension stages of the plant lifecycle. With advanced program templates, filters, and other types of equipment commonly used in the field, AD Suite improves engineering efficiency and helps to ensure uniform quality. It is able to centrally manage the functional design documents that provide the basis for control system engineering, along with all the control program master data stored in the Centum database. This simplifies history management when programs are modified and ensures that the latest design information is available when system expansion, modification, or maintenance is performed.

3. FieldMate Validator: The FieldMate Validator N-IO loop commissioning software is a software tool used to verify the wiring and relevant operations for any newly installed field instrument or field I/O device. When FieldMate establishes a connection with an N-IO device, the FieldMate Validator tool can check in real time the wiring of all field instruments, based on the control loop I/O information in the control system’s application software in order to verify that they operate correctly.

Agile project execution

Yokogawa executes projects with a combination of delivery excellence and smart engineering. With the release of the new Centum VP R6, Yokogawa incorporates the best practices of project execution with the introduction of APEX – Agile Project Execution. APEX is a methodology to execute all projects in a cost efficient manner by removing waste and reducing cost.

Conclusion

The combination of the newly designed technologies will deliver benefits to customers in a way previously unimagined. Since the release of the Centum integrated production control system in 1975, Yokogawa continually strives to improve this platform by incorporating the latest technologies. In 2008, Yokogawa released Centum VP, the latest generation of this series. To date, more than 25 500 Centum series systems have been delivered around the world. Yokogawa’s Centum VP R6.01 is scheduled for release in May 2015 in southern Africa.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved