In a wide range of industries, solutions are used for the detection of misshapen objects or objects of varying height. This often leads to high costs, especially through complex and expensive installation. Reliably detecting the leading edge in objects of varying height generally requires the installation of two photoelectric sensors – one on top of the other. A similar situation occurs when detecting flat and misshapen objects on the same belt, with the added problem of expensive and time-consuming cabling. Sensors with light band are the right solution here.

SICK Automation’s Ax20 array sensor

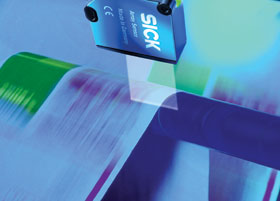

‘Line-for-line further ahead’ is what the Ax20 array sensor promises. The sensor has a high-resolution line array with which the most varied of objects can be detected with a repeat accuracy of up to 35 μm. Whether for detecting edges, inspecting material thicknesses or determining positions – the rapid line sensor, offering a hitherto impossible level of compactness and flexible mounting, opens up new automation solutions.

The Ax20’s scanning method of operation, as a result of which no supplementary reflector is required, is a major advantage. The measurement area can be up to 30 mm wide. Its adjustment is particularly easy thanks to the visible white light. In addition, the sensor is highly immune to ambient light and always supplies precise and reliable results regardless of the reflectivity properties of material surfaces – without any need for teach-in.

Of interest in numerous tasks

With its compact housing and appropriate mounting accessories, the Ax20 offers a high level of installation flexibility. This is as important for applications in packaging machines, in the print and paper sector, or in metal processing, for example, as the numerous ways in which the measurement values can be used. Typical areas of use for the scanning line sensor include the provision of measurement values for controlling the sides of webs of endless materials such as foils, paper or fleeces, whose passage through a machine can be regulated according to the signals transmitted via the analog 4-20 mA output. Detection can take place both via the edge of the web and on the basis of a line on the material. The continuous application of a material, e.g. a strip of glue applied by a glue applicator system, can be detected and tracked with maximum precision. The Ax20 also offers interesting opportunities in the area of position detection. The position of, for example, sheets of paper, flat workpieces or electronic cards can be reliably determined with the assistance of the Ax20.

For more information contact SICK Automation SA, +27 (0)11 472 3733, [email protected], www.sickautomation.co.za

| Tel: | +27 10 060 0550 |

| Email: | [email protected] |

| www: | www.sick.com/za/en/ |

| Articles: | More information and articles about SICK Automation Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved