End-user details

Name: Details withheld at reviewer request

SI Details

Name: Kobus Sutherland

Designation: Director

Company: Process Design and Automation

Phone: +27 (0)12 547 6524

E-mail: [email protected]

Product details

Product name and version: Adroit Scada

Vendor: Adroit

Phone: +27 (0)11 658 8100

E-mail: [email protected]

URL: www.adroit.co.za

Application details

Location: Franklin Electric SA, Edenvale, South Africa

Industry: Manufacturing testing

Date project started: 2012-12

Date project completed: 2013-12

Application: Testing system for water pumps

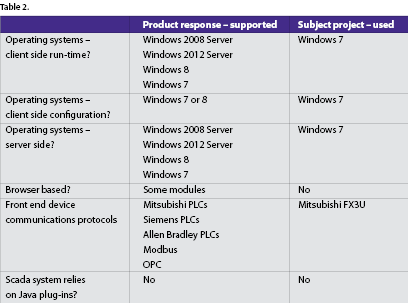

Server OS: Windows 7

Client OS: Windows 7

Application statistics

Tag count: 75 PLC tags and 250 local tags

Updates per day: We log 300 records of pump data a day to an MSQL database

Disk space for one day’s updates: 96 Kb

Physical I/O count: DI 48, AI 12, AO 4

Front ends: FX3U-32MR/ES, FX2N-4DA, FX2N-16EX-ES/UL, FX2N-8AD, FX3U-4AD, FX3U-ENET-ADP, AB VSD

Licences: 1 * 75 Tag Adroit 8 – Smart UI

Scada configuration man-hours: 160

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

Application to test water pumps against known criteria and record test results.

Q: What was the primary motivation for the project?

The previous testing method was time-consuming and could not meet the required test throughput of one pump every 30 minutes.

Q: What were the main goals established for the project?

* To achieve a particular throughput of pump tests per day.

* To log test information in a database.

* To easily print pump performance reports.

Q: In the procurement decision-making process what were the primary considerations that influenced the product selection?

Price and supplier capability.

Q: What Project Management principles and/or methodologies did you employ as end-user to mitigate risk, ensuring the project came out on time and within budget?

Followed DSDM Consortium principles for Agile Project Management.

Licensing, maintenance & support

Q: How is after-sales support handled on this application?

On an ad-hoc basis.

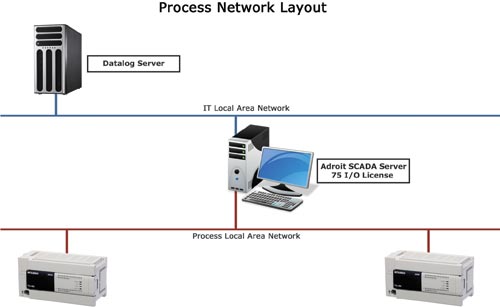

Architecture, integration, reporting and archiving

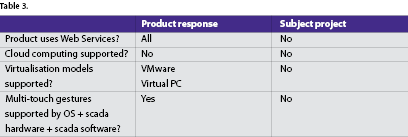

Q: Is the scada system integrated onto an intranet or the Internet?

Yes, for remote monitoring over plant network.

Q: Have any production benchmarking tools been configured as part of the scada system?

Not in the traditional sense. However, the benchmark curve for each pump model is on the system and is used to evaluate the pump under test to pass or fail the pump.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Ease of use and price.

SI Responses

Project details

Q: What tools were used to minimise the man-hours taken?

Adroit wizards and the templates functionality of Smart UI.

Q: What human factors were taken into consideration as principles or development standards in the HMI design process?

To minimise the need for the operator to enter data via the keyboard. Most data is scanned or selected from drop down boxes.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Standard library images.

Q: How would you describe the library of graphic images?

Comprehensive and new.

Q: What are the key physical communication layers and communication protocols employed in the system?

Ethernet and RS-232.

Q: What is the network speed and communications medium of the fastest link in this project’s scada network?

100 Mbit/s over Ethernet.

Q: What specific custom code or scada scripts were written for this project?

We used scripting to change the raw and engineering limits of the analogue signals depending on which instruments are used and to log data to a CSV file.

Project management

Q: What Project Management principles and/or methodologies did you as SI employ to mitigate risk and to ensure the project came out on time and within budget?

Followed DSDM Consortium principles for Agile Project Management. Scope creep reduced through formalised change control.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

By using the services offered by the OS.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

Yes.

Q: In what ways is this project’s hardware architecture optimised for patch management and antivirus management?

It is not.

Q: What configuration backup and data archive backup methodologies have been adopted?

Information unavailable. Managed by end-user.

SI conclusion

Q: What impresses you most about the architecture?

Open standards, wide range of drivers and the ability to upgrade.

Q: What impresses you the most about the engineering / configuration aspects of the product now that it is in operation?

The new designer environment is powerful and simple to use through the functionality of the new step-by-step wizard configuration.

Q: How would you rate the ease of use of the historical reporting system?

Very easy.

Vendor responses

Product

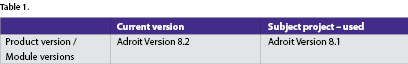

Q: Vendor comments on product / modules?

Adroit 8 Smart SCADA enables users to create impressive solutions using very simple configuration tools.

Operating systems / VMware

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

Adroit SCADA is licensed against the number of scan points (I/O) to the PLC and remote clients. Additional value-add tools such as Alarm Management and Overall Equipment Efficiency (OEE) can be purchased.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

The Adroit licence is a once-off purchase for a particular main version.

Q: What upgrade agreements are offered?

Minor upgrades (version 8.1 to 8.2) and patches are offered free of charge.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Telephonic and email support is offered free of charge. Training and in-office support is available to clients.

Q: Do you have a documented process in place to manage and test OS patches and to release scada system software patches?

When a new OS patch is released, a product surface test is conducted for the installation and operation of the Adroit SCADA. If incompatibilities are identified, these will be fixed and Adroit will release a new update which is compatible with the latest OS update.

Technology incorporated

Q: What changes have been introduced into the product in the last 12 months?

Support for web deployment.

Integration and reporting

Q: What generic and/or product specific interfaces does the product have iro well-known MES packages?

SAP (SAP Netweaver certification) and SYSPRO. Data is logged from the scada directly into a database from which the MES package fetches the data.

Q: What native historical data reporting options are available?

Adroit SCADA Intelligence on top of Microsoft SQL and Adroit native logging mechanism.

Security and data protection

Q: What authentication, authorisation & role management models are available for the runtime environment?

Adroit can utilise its own authentication model or use Microsoft OS functionality.

Unique selling proposition (USP)

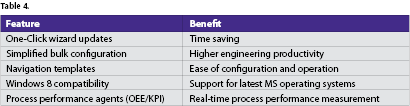

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

To view the unabridged version of this scada review, visit http://instrumentation.co.za/+C18948

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved