After the mill crushes, shreds, or presses the cane or beets to extract juice, it adds calcium oxide (milk of lime). The calcium oxide raises the juice to 11 pH or slightly more. The water in the juice reacts with the calcium oxide to form calcium hydroxide. The chemical addition has three desirable effects:

* The high pH prevents the sugar from becoming starch or reverting to non-sucrose forms.

* Organic acids are changed into salts for later removal by precipitation.

* Foreign matter is kept in suspension for removal by filtration.

To prevent scale build-up in subsequent stages, the mill must remove the excess lime via carbonation.

Introducing carbon dioxide

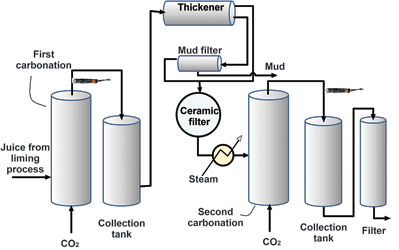

The injection of carbon dioxide, called carbonation, usually occurs in multiple stages. Carbonation precipitates the lime as less soluble calcium carbonate (limestone) and takes place by introducing carbon dioxide gas into the bottom of each tank as shown in Figure 1. Carbonated juice then overflows at the top of the tank for collection. Juice exiting first carbonation should be near 11,2 pH at a temperature of 88°C. Carbon dioxide saturation at the tank exit indicates the end point of the reaction.

The carbonated juice and calcium carbonate precipitate travel from the collection tank to the thickener or mud-settling tank, where the two juices clarified and muddy are separated. The muddy juice is filtered and this filtrate and the clarified juice are blended and sent through ceramic filters. The filtrate is heated to 97–99°C and then fed into the second carbonation tank. Once the second carbonation is complete (pH = 8,7 to 8,8 at 98°C), the juice goes to a collection tank and is again filtered.

Challenges in measuring pH

Sugar refining is a high-temperature, caustic process requiring tight pH control in almost every stage. Because the process is so physically demanding, in the past pH measurements were typically made in cooled sample lines (introducing significant lag time) or via grab samples (even longer lag time).

Attempting to control a nonlinear variable, such as pH in a continuous, dynamic process using these methods can easily lead to loss of process control. Prior to improvements in both pH glass and reference technology, online measurements were virtually impossible. Excursions of pH regularly occurred, and shutdowns were common.

The ABB Solution: TB551 and TBX587 pH sensors

Most sugar mills will operate through a growing season (a ‘campaign’). The campaign will be three to six months, depending on whether beet or cane sugar is the raw material. A pH sensor that can last through the entire campaign is often considered a success.

During carbonation, the pH must be high enough to remove lime in the form of calcium carbonate (limestone). But if the pH becomes too high in the first carbonation then the calcium will actually complex with the sucrose and negatively affect yields.

For these applications ABB’s Twist Lock TB(X)551 sensors are ideal for sample line installations. The bayonet style mounting facilitates sensor removal for cleaning and calibration. If the pH sensor is inserted directly into the process then ABB recommends a retractable sensor with extraction housing. The extraction housing has flushing ports which can be used to loosen congealed sugar and particulates. The TB(X)587 or TB(X)557 represent good retractable sensors that work in these processes.

Sugar mills should specify the coat resistant ‘J’ glass electrodes for all carbonation applications. The Wood Next Step Reference can serve for the applications below 11 pH. Teflon should be the material of choice above 11 pH. Measurements should not be made on the carbonation tanks because coating will become a much bigger issue than on flowing pipeline applications.

For more information contact Jacolize Goosen, ABB South Africa, +27 (0)10 202 5000, [email protected], www.abb.com/za

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved