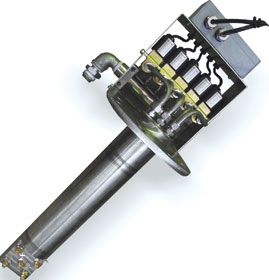

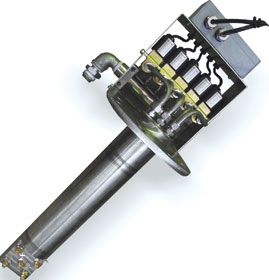

New desuperheater

February 2013

Valves, Actuators & Pump Control

PSV Mitech has launched a new type of desuperheater, which may also be used as an attemperator, with high turndown, good controllability and no moving parts in the steam flow. No additional control valves, steam assist or instrument air are required, only water, power and position signal. The eSteam desuperheater is a low maintenance and low cost solution for cooling superheated steam to within a few degrees of setpoint. It is designed for steam with flow rates up to 100 t/h at temperatures up to 500°C and pressures to 40 barg.

With five to seven nozzles, the unit can cover a wide range of requirements. Fine temperature control of ±1°C is achieved by controlled pulsing of the solenoid valves, each of which feeds high pressure water to a spray nozzle. This is the primary advantage of this system – the full available water pressure is applied across the nozzles when they are operating. In a conventional desuperheater an upstream globe control valve controls the water flow rate so that when a low water flow rate is required, the globe control valve closes and increases the pressure drop across the valve. This results in a low pressure drop across the nozzle which means that the water does not spray properly. In the eSteam design, low flow rates are achieved by reducing the amount of time the nozzles spray. A water turndown of 20:1 is achieved by varying the number of nozzles in use and the proportion of the sample time that one of these is open. Typically, downstream steam temperature is cooled to within 2–5°C of the saturation temperature.

The eSteam desuperheater can be used with water flows up to 12 t/h with up to 140°C water injection temperature at 20 to 40 barg pressure. The nozzles are sized according to the required water flow rate needed for the given steam parameters.

PSV Mitech’s custom designed microprocessor controller allows for smooth transitions across the turndown range and also monitors the number of cycles completed by each solenoid, spreading the load across all five and thereby increasing the overall lifespan of the unit.

The system components include nozzles, sparger, solenoid valves, manifold and controller enclosure. Temperature feedback is via the control room in the form of a 4–20 mA position signal to the desuperheater.

For more information contact Greg Walker, PSV Mitech, +27 (0)11 657 6000, [email protected], www.mitech.co.za

Further reading:

Developing solutions for SA’s wastewater challenges

Valves, Actuators & Pump Control

KSB Pumps has a proud global legacy in the development of self-priming pump technology, which reflects decades of engineering innovation and application expertise. Building on this foundation, KSB’s AU series has extended the company’s self-priming expertise into screened wastewater handling, which meets the growing needs of municipal and industrial sectors worldwide.

Read more...

Helping to solve wastewater challenges

Valves, Actuators & Pump Control

KSB Pumps and Valves is doubling its efforts to help government and municipalities find practical and technical solutions to the growing wastewater challenges gripping large parts of the country.

Read more...

Ultra-durable stainless steel submersible pumps

Valves, Actuators & Pump Control

KSB Pumps and Valves has launched a rugged stainless-steel submersible pump range designed for deep borehole use and other demanding freshwater and saline pumping applications.

Read more...

Industrial valve solutions

Bearing Man Group t/a BMG

Valves, Actuators & Pump Control

BMG’s Fluid Technology division supplies and supports an extensive range of components for fluid technology systems. These include valves, hydraulic hoses and fittings, accumulators, cylinders, heat exchangers, hydraulic motors and hydraulic plumbing, as well as pumps and reservoir accessories.

Read more...

New wastewater pump for local municipalities and industries

Valves, Actuators & Pump Control

The latest wastewater pump from KSB Pumps and Valves is making waves in the industry due to a host of new features that provide users with an ultra-durable long service pump with fewer blockages and a lower maintenance requirement than traditional pumps.

Read more...

The critical role of check valves in fluid systems

Valves, Actuators & Pump Control

In fluid power systems, the performance and reliability of the entire operation often hinge on components that are small in size but significant in function. Among these, the check valve stands out as a fundamental yet frequently overlooked element.

Read more...

ENERGYValves expands operations

Valves, Actuators & Pump Control

ENERGYValves is expanding its operations with a new facility in Cape Town. The new premises will significantly enhance the company’s capacity to serve the Cape Town market and surrounding areas.

Read more...

Pumps lead the way with advanced technology

Valves, Actuators & Pump Control

The KSB GIW MDX pump has consistently represented a major leap forward in mill duty applications, with KSB relying on customer feedback to improving the design continuously.

Read more...

Wireless leak detection valve

Valves, Actuators & Pump Control

Designed to prevent water leakage by automatically shutting off the water supply when a leak is detected, the Runxin F104 wireless leak detection valve is one of the latest offerings from Allmech.

Read more...

Ball valves and actuators optimise HVAC performance

Schneider Electric South Africa

Valves, Actuators & Pump Control

Schneider Electric offers the full range of innovative SpaceLogic and EasyLogic ball valves and actuators. These cutting-edge products are designed to optimise HVAC system performance, ensuring comfort and energy efficiency in commercial and residential buildings.

Read more...