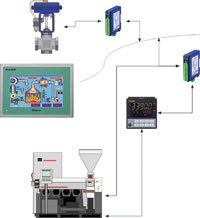

Following on the success of its process controllers, transmitter modules and paperless process recorders, Temp-Tek has turned its attention to HMIs, specifically the Brainchild range. Using its experience in many different fields of process control gained from hundreds of process lines all over the world, Brainchild began development of its HMIs with integration and ease of use in mind. The ethos of user friendliness at the core of the development process necessitated that the hardware development team worked closely with the panel studio development team to ensure the most accessible, unencumbered and powerful user experience possible. With this development studio users of any level of experience can unlock the full potential of these HMIs and their many advanced features. This new range easily integrates with existing PLC systems, I/O modules and process controllers of all kinds and brands. The OPC tag database combined with the powerful features of the HMI communications system allow the HMI to act as a data exchange gateway between two PLCs, facilitating easy integration in both new and existing systems.

Brainchild’s range of distributed I/O modules has been designed to work and integrate with the new HMIs, as well as provide real-time data acquisition and monitoring. These modules are available in many varieties such as thermocouple, RTD and 4-20 mA input as well as digital input and outputs and combinations of the two. Using the Modbus RTU protocol on an RS-485 connection, these units can be integrated into existing PLC setups. They can also be connected directly to a PC using Brainchild’s DAQ (data acquisition studio) or a proprietary suite such as 'MoniLab'. Using this direct connection method even the most basic of microcomputers can become an extremely powerful data-logging system. Connection of up to 254 distributed 8 inputs allows up to 2032 inputs to be monitored.

Standalone data acquisition supported by wireless transmission modules

While low cost PLCs are becoming more prevalent in processing today, more complex processes require more complex PLCs which not only carry with them multifarious programming techniques but a substantial increase in cost as well. Using Brainchild’s new HMI smart panel platform in conjunction with the distributed I/O modules can help circumvent the need for a PLC altogether. Using the powerful toolset available in the Panel Studio, engineers can create an all in one data acquisition station, operator panel and control system in a relatively short space of time.

Another challenge faced by engineers when designing new, or integrating existing, systems, are environmental factors such as temperature, dust, EMI, distance and chemical atmospheres. Brainchild’s new range of wireless transmission systems can be a great help in dealing with these issues. The new PC-W module can take two serial inputs (RS-232, 422 and 485) and an Ethernet connection and convert them into a Wi-Fi Ethernet signal to be broadcast over an existing Wi-Fi infrastructure or an ad hoc configuration between two of these units. This allows engineers to escape the short falls of conventional cable methods for transmission of various reference signals, such as thermocouple signals and 4-20 mA loops. These powerful and user friendly modules employ a browser based GUI for the quickest and simplest of setup procedures and have support for even the most complex network configurations.

The new system in action

An example of this could be found in a processing plant where the chemical nature of the atmosphere would severely damage and corrode a set of cables. Long distances and high network traffic were other obstacles that Temp-Tek had to overcome recently when it aided a plant in resolving just such a situation. Using the Brainchild PC-W module in conjunction with distributed I/O modules not only made it possible, but the solution came in at about one fifth of the cost of the alternative using special corrosion resistant cables. This solution also allowed multiple user access to the acquired data in real-time over a large scale network throughout the plant. Brainchild’s DAQ studio provided an easy to use interface to facilitate this, as well as data archiving for later review.

Brainchild’s new range of HMIs, I/O modules and networking devices has created a low cost, high quality and easy to use platform for the complex and environmentally challenging process conditions that engineers face today.

| Tel: | +27 11 465 8066 |

| Email: | [email protected] |

| www: | www.temptek.co.za |

| Articles: | More information and articles about Temp-Tek |

© Technews Publishing (Pty) Ltd | All Rights Reserved