Anyone who needs to keep processes running needs level measurement technology that measures reliably under all conditions – whether in water treatment, on chemical tanks, or with bulk solids in silos and open stockpiles. However, what is needed is not always the most ‘fully featured’ solution, but the smartest one. This is often a simple solution that is compact and economical, is able to monitor auxiliary or standard processes and is highly precise and dependable. This ensures all processes in a plant interact perfectly, regardless of the demands placed on the respective measuring points.

This is exactly what VEGAPULS radar transmitters of the BASIC series do. Since 2020, the BASIC instruments have established themselves as the standard for measuring points where high-end technology would be too costly and complex. Despite their low cost, they still perform significantly better than previous level measurement technologies like ultrasonic.

A leading market position results from experience

In 2020, when VEGA first launched the new radar technology of the BASIC series in a compact design, one simple idea was given priority. These instruments are not intended to take the place of radars in the PRO series which are designed for use under extreme conditions. Rather, they are a well-designed supplement technically reduced to the basics, which is what matters in standard applications. They set the standard in terms of price/performance, reliability and simplicity, whether deployed in open water, silos, sumps or tanks.

The 500 000th VEGA radar instrument from the BASIC series was recently delivered to a leading European company that makes sustainable building products. There, a VEGAPULS 31 transmitter measures with great precision up to 30 metres deep in storage silos. Neither dust nor noise nor coarse material influences the measuring result. Previously, a complex and expensive solution would have been required for such conditions. Today, this task is performed by a transmitter that can be installed and set up in just a few minutes without special knowledge and preconditions.

Supplement, not replacement

VEGA’s compact radar transmitters do not replace the high-end radar level measurement technology with which VEGA has been leading the way for over 30 years. Rather, they supplement it in a targeted manner, especially where older technologies like ultrasonic are increasingly reaching their limits. Technical innovation has made it possible for radar to not only deliver better level data, but also to be economically competitive. The 80-GHz radar chip, which VEGA developed specifically for this task, plays the central role with a unique compact design, low energy consumption and optimised frequency ranges. “Our goal was to apply radar transmitters exactly where ultrasonic technology used to dominate, but with better performance and minimal effort to replace existing instruments,” explains product manager, Jürgen Skowaisa. “Mount, connect and you’re done.” The new radars can be installed in just a few minutes, even on existing ultrasonic measuring points. No extensive training or system conversion is required. Radar has been such a success that VEGA has now discontinued its ultrasonic production. Radar is no longer the more expensive alternative, and it is superior in every respect.

Ex has never been so easy

VEGA is currently the only supplier offering radar level sensors with fully encapsulated electronic components and connection cables. This enables deployment in hazardous areas of Zones 1 and 2, without additional barriers and special accessories. Existing infrastructure can continue to be used as standard cables are sufficient and colour coding is not necessary. Furthermore, VEGA sensors are so robust that they are approved for both dust-Ex and gas-Ex applications. For plant operators, this means no additional costs and particularly simple installation or retrofitting. As a bonus, they save a lot of resources in the control cabinet as well as in project planning.

Skowaisa, who oversaw the development of the technology right from the very beginning, recalls: “When we started, our primary focus was on the water and wastewater sector. But it quickly became apparent that all industries that process liquids or bulk solids want more cost-effective and reliable solutions for their peripheral applications”. Reducing the design to the essentials was not an end in itself, but a targeted response to all the requirements in applications where extreme process conditions, hygienic standards or SIL levels are not a factor, but rather stability, precision and simple integration.

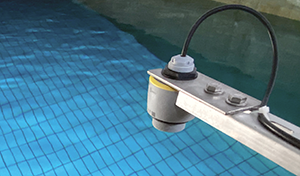

Flooding is no problem

With direct cable connection these radar transmitters were initially developed with challenging water and wastewater applications in mind, and this is especially evident in the materials used in their construction. Their high-quality PUR cabling is chemically resistant. In addition, robust materials like the PVDF used for the housing and cable entry, as well as the fully welded and potted construction, ensure it is fully watertight, even when submerged for days at depths of up to 30 metres. This sets VEGA transmitters apart from the lower-quality equivalents offered by other suppliers. “Our goal was high performance and reliability, which is what our customers have come to expect from the PRO series instruments,” says Skowaisa. “This level of quality is evident throughout our entire portfolio – it’s simply what people expect from us”.

Many extras at no extra cost

The issue of data availability and diagnostic capability deserves special attention. VEGAPULS transmitters offer a comprehensive range of functions right out of the box, at no additional cost. For setup, the free VEGA Tools app delivers a user-friendly interface, exceedingly simple operation and diagnostics via smartphone. For example, the practical Backup and Restore feature is invaluable, saving time during maintenance and transmitter exchange. For communication and evaluation VEGA relies on simple, transparent solutions without hidden, costly licensing models or additional software. “Good radar measurement technology proves itself through performance in everyday use,” emphasises Skowaisa. “That’s why we believe that simpler is often better.”

Everything but complicated

This BASIC radar series has become a permanent fixture in the world of measurement. Although the initial focus was on the water sectors, it now extends to all industrial sectors where liquids or bulk solids are measured. Basically, this is wherever standard measuring points form the backbone of a process and they require maximum reliability. The high-end VEGA PRO series radars, suitable for high pressures, extreme temperatures or SIL applications, are often excessive for these tasks and therefore less cost-effective. Compact radar transmitters from VEGA fill this gap perfectly, delivering the essentials with maximum efficiency and without compromising on quality. Simply install the transmitter and then forget it.

| Tel: | +27 11 795 3249 |

| Email: | [email protected] |

| www: | www.vega.com/en/home_za |

| Articles: | More information and articles about VEGA Controls SA |

© Technews Publishing (Pty) Ltd | All Rights Reserved