BMG, the authorised distributor of a wide range of quality branded engineering consumables, is concerned about the proliferation of counterfeit merchandise, and the dangers associated with using inferior goods. “While visiting various plants, we noticed that many engineers and foremen believed they were using genuine Nord-Lock washers. However, on closer inspection it was clear that in many cases they were using inferior copies of Nord-Lock washers,” says Maryna Werner, BMG’s fasteners sales manager. “Catastrophic failure of critical bolted joints is a risk when inferior copies are used, especially when the quality and origin is unknown or when no support or warranties are available.”

BMG’s Nord-Lock bolt securing system is based on advanced wedge-locking technology, designed to safely secure bolted joints that are exposed to severe vibration and dynamic loads in extreme conditions. This advanced system improves personal safety, reduces the risk of lost production or material damage due to bolt failure, and lowers maintenance requirements.

Nord-Lock washers are rigorously tested throughout the production process, with quality and safety approval from independent institutes and certification authorities. This gives customers the assurance that they are using the market’s safest bolt securing elements. In fact, the Nord-Lock group is so confident in the quality, reliability and efficacy of its locking washers that it offers a full lifecycle warranty on its washers.

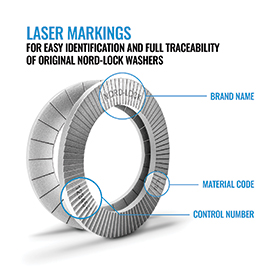

Nord-Lock quality washers, which are supported nationally by BMG, are laser engraved with the dependable Nord-Lock brand and batch numbers to ensure identifiability and traceability. Data sheets and material certificates are available on request.

“We encourage consumers to take special care when sourcing products from non-authorised suppliers. There is no way of knowing whether counterfeit copies of original Nord-Lock washers have gone through proper testing or what materials they’re made of, which jeopardises their safety and reliability,” says Werner. “Authentic Nord-Lock washers are a safe and reliable bolting solution that also saves time and money due to less maintenance and reduced downtime.”

Nord-Lock has developed various measures to prevent non-verified Nord-Lock washers from reaching end users. This initiative extends from educating the market about counterfeiting issues to original product design features.

The Nord-Lock range of securing washers, distributed and supported by BMG, is the only brand on the market that currently displays the CE quality mark of approval from leading global authorities. The prestigious CE marking is certification that these wedge-locking washers adhere to stringent safety and quality regulations required in many industries.

The BMG team encourages consumers to take special care when sourcing products from non-authorised suppliers. By choosing original Nord-Lock washers for a safe and reliable bolting solution, consumers have the assurance of compliance and safety. With a locking mechanism that uses tension instead of friction, Nord-Lock washers keep bolted connections tight and secure. Operators can rest assured that bolts will stay in place, even when subjected to severe vibrations, heat cycling and dynamic loads.

BMG offers a technical advisory service to determine the dimensions and load conditions of existing or required bolted joints. Current tightening methods are evaluated, and bolt preloads for reliability and durability are calculated by the highly skilled team.

| Tel: | +27 11 620 1500 |

| Email: | [email protected] |

| www: | www.bmgworld.net |

| Articles: | More information and articles about Bearing Man Group t/a BMG |

© Technews Publishing (Pty) Ltd | All Rights Reserved