Miniature drives and microdrives can be found in virtually all areas of automation technology, and have a wide variety of applications. These range from medical technology and laboratory automation, to general machine construction and intralogistics, through to aerospace. In all areas, the small drive systems play a role in ensuring that the associated automation solutions function with optimum process safety, reliability, and cost-effectiveness. This also applies to handling applications. In slimline, yet high-torque swivelling-rotary modules, these drives ensure that even large workpieces are moved precisely, both in the case of fast screwdrivers, and in automatic rotary handling, assembly and testing systems.

Anyone looking for an efficient and space-saving solution for typical movement sequences that occur in handling and assembly technology, such as turning, swivelling, screwing, rolling, or coiling can turn to the swivelling-rotary modules of the ForTorque series from the kinematics specialist, Jung Antriebstechnikbased (JA2) in Wettenberg, Germany. These slimline infinite rotary units are ideal for the highly dynamic rotation of large, high-inertia workpieces and eccentric grippers, and also for use in screwing and coiling technology.

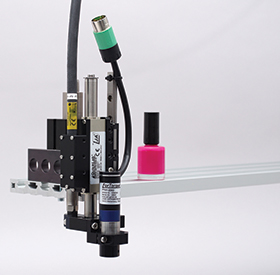

A typical application case for the miniature swivelling-rotary modules is screwing the caps on small cosmetics or pharmaceutical containers in constrained spaces on fully automated packaging lines. The modules are also suitable in cases where grippers or workpieces need to be swivelled when assembling or separating products. Designed as a modular system, six sizes are available. This covers peak and continuous torques of 0,3 and 0,14 Nm to 4,0 and 2,6 Nm respectively. The inertias of the load can be between 2,0 and 200 kgcm2. This provides the most suitable solution for accurately angled movement and positioning for a wide range of different handling and assembly tasks.

To reduce the load on the output shaft of gearheads in the case of high external moments of inertia, the output plate of the four larger module models has an extremely rigid bearing consisting of two thin-section bearings. The swivelling-rotary module with 40 mm diameter can additionally be equipped with a fluidic rotary joint for pneumatics or vacuum to supply a pneumatic gripper with compressed air, for example.

“The drives are the heart of our modular automation system and the requirements placed on them are very high,” says Wilhelm Jung, managing director at JA2. “The motors must operate highly dynamically, be precisely controllable, and have suitable dimensions.” In the case of the ForTorque modules, for example, the brushless DC-motors of the B and BX4 series from Faulhaber proved convincing. The motors with their two-pole and four-pole technology are extremely compact. The used variants of the B series with diameters of 16, 20 and 35 mm are just 28, 36 and 68 mm long respectively, but deliver continuous torques of up to 168 mN in the case of the largest variant. This also applies to the BX4 series. “Here we use Faulhaber motors with 22 or 32 mm diameter and continuous torques of 18 and 53 mNm respectively,” reports Jung.

The motors are used in the ForTorques up to speeds of 8000 rpm. Different gearheads, including zero backlash planetary gearheads from Faulhaber, provide gear reduction. Ultimately, the gearhead technology with the respective maximum input speed determines the limit for the maximum motor speed. “We then select the reduction ratio according to the application,” continues Jung. “In this way, we can influence the extent to which the external moment of inertia is reduced by the square of the reduction. The motor can then be precisely regulated, unaffected by the lever. When selecting the gearheads, we paid particular attention to the efficiency of the gearheads, because the better the efficiency, the more precisely the torque applied at the gearhead output can be determined from the motor current. This is a key feature of screwing applications where delicate plastic parts need to be screwed on with a defined torque.”

Single-cable technology for fault-free control

All swivelling-rotary modules are connected and controlled using a standardised bayonet connector, single-cable technology and a motion controller. In automation systems, however, the switch cabinet is usually some distance from the actual drive. “Between the motor and the controller in the separate switch cabinet, there can then be 10, 20 or more metres,” says Jung. There is therefore a special multi-shielded cable that transfers the motor power and the position sensor signal between motor and controller up to 30 metres without interference.

“We also offer motion controllers from Faulhaber,” adds Jung. The linear drives produce an exceptionally good relationship between linear force and current, with high dynamics and no cogging torques.

| Tel: | +27 76 563 2084 |

| Email: | [email protected] |

| www: | www.hornet.cc |

| Articles: | More information and articles about Horne Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved