The strategic alliance between Bearings International (BI) and I-MAK, initiated in February 2019, signalled a new chapter in BI’s mission to augment its selection of premium brand offerings in a bid to deliver top-tier strategic solutions to Africa’s sub-Saharan region.

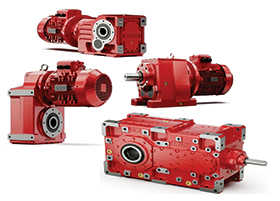

From planetary, worm and aerator units to flagship products like its inline helical, parallel shaft, helical bevel and monoblock IGU, I-MAK provides over one million product references, ensuring a solution for every specific industrial need.

General manager, Robert Sillis says: “Our partnership with I-MAK presents the cornerstone of BI’s strategy to provide high-quality, reliable solutions tailored to meet the diverse needs of a raft of industrial applications. All the products have a very high South African added value which, coupled with I-MAK’s dedication to innovation, quality and precision, aligns perfectly with our mission to enhance production uptime and efficiency, delivering our value proposition of keeping customers ‘in motion’.”

Business unit leader, Kobus Groenewald unpacks the unparalleled advantages that the I-MAK range offers customers: “These are world-class quality, affordable, two-year warranty products that are backed by specialist local and international support.”

I-MAK boasts a solid footprint in sub-Saharan Africa through its partnership with BI, alongside extensive leading brand presence on the rest of the continent, up to North Africa. This expansive reach is testament to I-MAK’s well-established reputation and extensive experience spanning over 50 years.

The I-MAK product portfolio focuses on essentially all industrial segments, with utilities, automotive and sugar identified as key sectors, while particular emphasis is placed on manufacturing, mining, FMCG, and water treatment due to their high growth potential.

I-MAK’s products are available exclusively for the sub-Saharan region via BI. They are comprehensive and include a wide range of gearboxes and drive solutions designed to address the most pressing challenges currently faced by the gearbox market. This is driving the need for better technologies, higher efficiencies, and durability in order to maximise uptime and optimise operations.

Supporting the extensive I-MAK product range is BI’s exceptional customer service, which includes 24-hour breakdown support and a fully equipped factory and engineering facility. This is fit for all customer- and application-specific design alterations and additions to standard equipment. This is all supported by national coverage through the organisation’s 42 branches, essentially providing customers with access to immediate and effective support whenever and wherever they need it.

“I-MAK is also doing its part by focusing on establishing a close partnership with local companies to support their growth and engineering development,” adds Groenewald. “Because I-MAK listens to its customers’ requirements, it is able to provide bespoke solutions outside its standard range of products.”

I-MAK differentiates itself by meeting and exceeding market expectations for technology, efficiency and durability through constantly improving its facilities, widening its network, and upgrading its equipment. This allows the company to align its product and services with dynamic market expectations. In Q4 2023, I-MAK further solidified its commitment to the South African market with the deployment of a country roadshow to showcase and unveil its cutting-edge products across BI’s extensive local branch network.

This initiative, which was hosted at various BI branches, also served to strengthen BI’s market presence, and equipped sellers with the knowledge and tools needed to present I-MAK’s value proposition effectively to customers. “This was an outstanding demonstration of our shared dedication to providing bespoke solutions and enhancing production uptime,” notes Sillis.

Through the strategic partnership with I-MAK and initiatives like the country roadshow, BI continues to lead the way in offering premium, innovative solutions that meet the evolving needs of the industrial sector across sub-Saharan Africa. The shared synergies with I-MAK make this a win-win partnership that emphasises BI’s dedication to expanding its portfolio with top-tier brands renowned for their innovation and dependability.

| Tel: | +27 11 899 0000 |

| Email: | [email protected] |

| www: | www.bearings.co.za |

| Articles: | More information and articles about Bearings International |

© Technews Publishing (Pty) Ltd | All Rights Reserved