The world of adhesives keeps expanding to accommodate applications with highly tailored tapes, foams and other products. However, automated tape dispensing systems have not kept up, and offer little flexibility to adapt to wide-ranging industry requirements. RoboTape offers a way out of the dilemma. Innovative Automation, a Canadian custom machine builder and systems integrator, has developed the platform by leveraging advanced robotics and flexible control technology.

The main pain point of the existing solution was the robot size and flexibiity, because most systems placed the tape spool at the end of the robot arm, along with an empty spool to catch the waste liner. Also, operators had to wait until the systems ran out of tape, put them into a safe machine state, and enter the cell to add more, which took away valuable production time.

“We came up with the idea of a remote feeding module that positions the spool outside the work cell. This is now patent pending worldwide,” says Zac Cutt, research and development group leader at Innovative Automation. “It also helps with the robot sizing issue, allows for larger spools, and increases system uptime. This is why big automotive clients are latching onto it; it’s currently the only solution that actually solves the entire problem.” RoboTape now catches and chops up the waste liner at the remote feeding module. The design optimisation drastically reduces the size of the robot needed.

Sean Robillard, in the Controls Department at RoboTape, appreciates the user-friendly software approach. “Operators can view all their inputs and outputs, toggle cylinders, lights and sensors, and adjust other aspects of the machine. “This is all bundled into the same TwinCAT package, so it speeds up engineering and keeps the HMI design clean.”

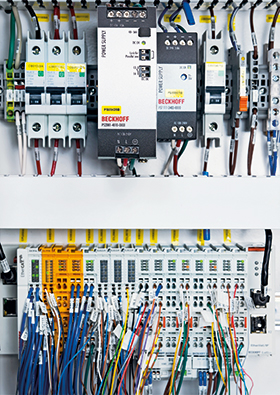

A CP6706 economy built-in Panel PC from Beckhoff offers ample processing power for the application. It is equipped with a dual-core Atom processor, 4 GB of RAM, a 40 GB CFast card, and a 1-second uninterruptible power supply (UPS). The IPC includes an 18-cm touchscreen for operator interface, and in conjunction with TwinCAT automation, the software is ready for cloud connectivity right out of the box.

The control system utilises the EtherCAT industrial Ethernet system for real-time communication to the robot and other field devices. The openness of EtherCAT with regard to integrating other protocols helps the RoboTape team connect a vast range of different robots and third-party devices, such as sensors and encoders, in customer facilities.

With TwinSAFE for system-integrated functional safety, the platform can protect plant personnel and equipment, according to the RoboTape experts. The remote feeding module enters a safe state when operators open its enclosure. This level of safety is required because a cutting blade utilised to chop the spent liner and other pinch points is contained inside the feeding module. For this purpose, TwinSAFE safe input and output terminals are used, that can be connected directly to the door of the robot cell, light curtains or floor mats. In this way, the need for conventional and complex hardwiring between safety devices is eliminated.

Support for end users

“Our systems average eight hours of runtime before refills,” Cutt says. “For instance, one customer processed more than 4000 metres of felt on a single spool, to make enough parts for about 2000 cars a day, while only changing spools once a week.” Another Tier 1 automotive supplier shrank the overall footprint of its assembly area by removing two manual taping stations. In addition, it reduced labour requirements at a time of skills shortages. As a result, the customer saved roughly 225 000 Canadian dollars a year on adhesive applications in one plant.

“Our new IIoT capabilities allow us to see which machine modes are activated, and for how long. So, if a system is in service mode for long periods of time, it could indicate it needs maintenance,” Cutt says. “We can see the machine’s overall equipment effectiveness, along with metrics like internal and ambient temperature, in order to optimise and improve reliability.”

“Consistent support and availability are the reasons why Beckhoff has proven to be a great choice, and we’re excited to continue working together in the future,” concludes Michael Lalonde, co-owner and president of RoboTape and Innovative Automation.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved