Within the framework of the energy transition from fossil-based fuels to renewable sources, hydrogen will play a significant role. Generation of hydrogen can be done via different routes, but the one through electrolysis, and in particular the alkaline electrolyser, is the focus here. The market for alkaline electrolysers is growing rapidly as these installations are often being used in combination with large PV solar fields and wind turbines, with the goal of relieving the electrical power grid. There is also a continuous search for optimisation in electrolyser operation and performance.

Against this backdrop, two German family businesses, SAMSON and KROHNE, have joined forces to form a new, innovative company, FOCUS-ON. KROHNE’s expertise in flow metering, combined with SAMSON’s strength in valve technology, resulted in a first for the company, FOCUS-1. This is an industrial flow control valve that functions and communicates completely autonomously.

FOCUS-ON drew on the expertise of design specialist, Spark to come up with four features of the FOCUS-1:

• A balance between design and function, between one-time cost and cost price, and between time-to-market and technological innovation.

• Suitability for potentially explosive atmospheres.

• User experience and usability.

• Ability to simplify and optimise a process plant.

The application study that follows relates to the use of the FOCUS-1 smart meter valve in alkaline electrolysers, and is based on proven experience with one of the biggest hydrogen electrolyser producers in the world. The project proves that the smart meter valve’s added functionality creates an ideal setup in alkaline electrolysers for reducing cost, and improving functionality and system performance.

Control requirements

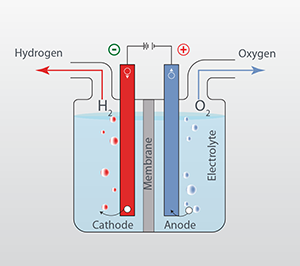

In an alkaline electrolyser, hydrogen is generated by splitting water (H2O) molecules into its two base molecules, oxygen (O2) and hydrogen (H2). This can be done by applying an electrical voltage across two electrodes inserted into a water-filled basin. The water in the basin needs to be electrically conductive, so that the electrons necessary for the reaction can flow from one electrode to the other. The required optimum conductivity is achieved by mixing potassium hydroxide (KOH) into the demineralised water in the basin.

As the water splitting reaction takes place, demineralised water needs to be added in the right amount in order to maintain the optimum KOH concentration. As the reaction itself is exothermic, the water in the basin needs to be circulated to maintain a homogenous temperature distribution, and to keep the temperature within limits.

Currently, the KOH concentration is measured by offline concentration sensors, or deduced by Coriolis mass flowmeters. In both cases, their output values go to a PLC, which then operates a valve that controls the flow of demineralised water into the electrolyser. As the circulation flow of the water/KOH mixture also needs to be monitored, a flowmeter and a temperature sensor are installed. Of course, in the case of the Coriolis mass flowmeter, the flowmeter would not be strictly necessary.

In this control setup there is a concentration sensor, a flowmeter, a temperature sensor, a control valve, and a PLC with corresponding software installed. Requiring all these individual sensors has consequences for the mechanical and electrical construction, installation labour, and hardware and software integration into the PLC. They will affect the dynamic behaviour of all of these components as one system. In short, it is a complex system, and it is a challenge to get the dynamic behaviour to where it should be.

The FOCUS-ON solution

As in the FOCUS-1, a smart meter valve, an ultrasonic flowmeter, and temperature and pressure sensors have been integrated with a control valve, together with powerful processing, data storage and control capacity, so the complexity of this application goes away. Now only one single device has to be installed, and this performs the flow control and KOH concentration measurement. As for the circulation flow control, the integrated temperature, flow and pressure sensors are paced at 10 Hz. The integrated PID control algorithm can drive the control valve very accurately and fast, resulting in corresponding process control.

The KOH concentration measurement, necessary to control the demineralised water flow, is an integrated standard feature that is generated by the smart combination of available sensor signals (sonic velocity, temperature and pressure). It is as fast as the other measurements, i.e., 10 Hz, it is very accurate (<0,4% relative uncertainty), and it comes as a standard feature of the FOCUS-1smart meter valve.

The FOCUS-1 valves used in alkaline electrolysers are the FOCUS-1 DN 50 smart meter valve for water/KOH circulation flow; the FOCUS-1 DN 50 smart meter valve for demineralised water flow; and the FOCUS-1 DN 100 smart meter valve for KOH crossover.

The benefits for the customer are:

• Comprehensive control and monitoring capabilities.

• Improved efficiency of electrolyser operation via accurate, stable and fast flow control.

• Electrolyser optimisation via direct KOH concentration measurement.

• All-in-one solution that significantly reduces complexity, cost, and installation effort.

• Additional data insights that lead to longer uptime of the electrolyser units.

© Technews Publishing (Pty) Ltd | All Rights Reserved