Macro benefits in micro applications

July 2023

Motion Control & Drives

With the micro-mobility market set to soar in the years through to 2030, NSK is in a prime position to help OEMs take advantage of this significant demand. The company’s bearings have all the strength, heat treatment and compact dimensional attributes needed to succeed in any project involving products such as e-bikes, e-scooters or cargo bikes.

According to a report released in August 2022 by market research specialist The Brainy Insights, the global micro-mobility market is set to reach $202 billion by 2030, representing an impressive growth rate of 17,45% during the 2022-2030 forecast period. Notably, the recovery of global tourism in the post-pandemic world is driving demand for micro-mobility and economical touring options. Transport modes of this type are also central to the plans of emerging smart cities. Such is the anticipated growth that a number of major automotive suppliers are currently looking at diversifying into the micro-mobility sector.

Of course, when demand for a solution is high, OEMs must identify robust technology partners able to demonstrate high quality, reliable products set against the backdrop of proven supply chain performance. Bearing suppliers are no exception.

With e-mobility applications comes a particular set of bearing requirements. Take e-bikes, for example. These machines are compact, yet relatively heavy loaded, as they must withstand high forces exerted by the rider, drivetrain and road. In direct correlation, bearings must also be compact, yet demonstrate considerable strength. A further demand is the need to minimise friction torque so that the e-bike is easy to handle.

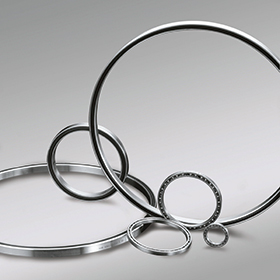

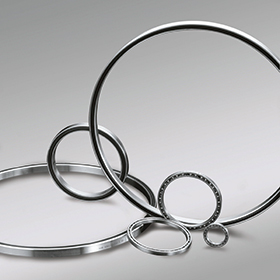

The requirement for compact dimensions is nowhere more notable than e-bike drive units, which need to be as narrow as possible despite having to house both an electric motor and a gearbox. To help facilitate this design demand, OEMs can turn to the proven thin-section bearings of NSK, which are able to withstand both high loads and torque. NSK can offer a broad range of standard thin-section bearings, and bespoke offerings, to fit customer-specific requirements.

Thin-section bearings from NSK feature robust seals to prevent the ingress of moisture and contaminants thrown up by harsh road conditions, thus maximising service life. Furthermore, their smooth running, low-friction characteristics help to enhance rider comfort and minimise noise.

The inherent strength of NSK thin-section bearings derives from a number of engineered features, including special materials and heat treatment, helping to prevent deformation under load. These bearings are also beneficial in applications such as electric mountain bikes, where due to the potentially demanding terrain, the bearing must facilitate effective torque transfer to the drive without friction loss.

In summary, NSK thin-section bearings contribute to product downsizing and lighter weight in all micro-mobility applications. Furthermore, with lower frictional torque and less torque variation, the bearings improve torque transmission and provide smooth rotation, while also supporting high speeds.

Further reading:

Novel bearing steel next generation of aeroengines

SKF South Africa

Motion Control & Drives

SKF continues to re-imagine intelligent and clean rotation with the development of an innovative temperature-resistant, corrosion-tolerant steel called ARCTIC15 designed for aeroengine bearings.

Read more...

Products from maxon

Motion Control & Drives

A wide range of new products is available from motion control specialist, maxon. with a diverse technology portfolio ranging from highly integrated robotic actuators to powerful servo drives and controllers.

Read more...

Actuators for precise hexapod movements

Motion Control & Drives

Aerotech, manufacturer of high-performance motion control and automation systems, is expanding its Automation1 platform. These compact hexapod devices enable the complete integration of six-axis motion systems into existing control

Read more...

SEW-EURODRIVE service centre transforms future of drive repairs

SEW-EURODRIVE

Motion Control & Drives

In a momentous step for the local industrial gearbox and drives market, SEW-EURODRIVE South Africa has formally opened a new service and repair facility alongside its headquarters in Aeroton,

Read more...

Strategic system upgrades beat mining obsolescence and drive productivity

Motion Control & Drives

Mining operations are under constant pressure to maintain output while controlling costs. One persistent challenge continues to confront the industry, knowing when and how to upgrade aging systems before they become a liability.

Read more...

Precision meets performance: The ELGD Axes Family from Festo

Festo South Africa

Motion Control & Drives

Festo has introduced the ELGD axes family, engineered for the demands of future-focused industries. With cutting-edge guide technology, exceptional rigidity and high load capacity, these axes deliver more performance within the same installation footprint.

Read more...

Condition monitoring in hazardous areas

SKF South Africa

Motion Control & Drives

SKF is further strengthening its condition monitoring offer portfolio by a newly developed hazardous area version of its Microlog Analyzer dBX portable vibration analyser.

Read more...

Rip-and-ship solution speeds up nuclear decommissioning project

Motion Control & Drives

When removing steam generators from decommissioned nuclear reactor buildings, the most economical method is to remove them in one piece. Mammoet was commissioned by Framatome to support with the removal of four steam generators from PreussenElektra’s Nuclear Power Plant Unterweser in Germany.

Read more...

WearCheck turns the focus on friction modifiers

Wearcheck

Motion Control & Drives

One of the most important features of a lubricant is the reduction of friction between two surfaces.A dditives like friction modifiers are added to perform this function. Wearcheck turns the focus on friction modifiers

Read more...

SEW-EURODRIVE transforms drivetrain uptime

SEW-EURODRIVE

Editor's Choice Motion Control & Drives

The DriveRadar IoT Suite from SEW-Eurodrive is an ideal solution for industrial condition monitoring. This powerful ecosystem of intelligent sensors, edge devices and cloud-based analytics ensures that customers have full visibility and control of their operations.

Read more...