AMETEK Land has supplied its LWIR-640 thermal imagers and NIR-B-2K-Glass cameras to leading glass manufacturing facility O-I Seville. Together, these instruments provide glass leak detection and furnace optimisation, creating benefits for safety, efficiency and sustainability.

The O-I Seville plant is a leading glass manufacturing facility that is committed to sustainability and innovation, producing high-quality glass packaging products for customers around the world. Located in Seville, Spain, it is operated by Owens-Illinois (O-I), one of the world’s largest glass container manufacturers.

The O-I Seville plant produces a wide range of glass packaging products, including bottles and jars for food and beverage, pharmaceuticals and cosmetics. The plant is equipped with state-of-the-art technology, including glass furnaces, forming machines and inspection systems, to ensure high-quality products, and has received several awards for its sustainability efforts, including the European Glass Packaging Award for Sustainability. In addition to its manufacturing operations, the O-I Seville plant also has a research and development centre focused on developing new glass products and manufacturing technologies. The centre works closely with customers to develop innovative packaging solutions that meet their specific needs.

O-I Seville was experiencing issues with glass leaks in its furnaces, which were causing downtime and reducing production efficiency. Additionally, the company was looking for ways to optimise furnace operations to reduce energy consumption and improve product quality. AMETEK Land supplied two technologies to support O-I Seville in achieving its aims: LWIR cameras for glass leak detection, and NIR-B cameras for furnace optimisation.

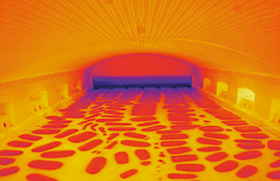

LWIR-640 long-wavelength thermal imagers were used to detect glass leaks underneath the furnace, including the side wall. Providing a full temperature measurement range of -20 to 1000°C in three ranges, these cameras can detect temperature differences between the glass and surrounding materials, which can indicate a leak. The LWIR-640 offers live, high-resolution imaging capabilities at 60 frames per second, allowing for accurate detection and precise identification of leaks.

Glass leaks can be hazardous to personnel and the furnace itself, so the LWIR-640 helped to reduce the risk of fires and improve overall safety. The ability to detect even small temperature differences also allowed for early detection of leaks before they became more severe and costly to repair.

NIR-Borescope-2K-Glass (NIR-B-2K-Glass) is a short wavelength radiometric infrared borescope imaging camera, designed to produce high-definition (1968 x 1476 pixels) thermal images, along with providing accurate temperature measurements from any of the three million temperature points in the image.

The dual-technology solution created several benefits for O-I Seville. By detecting and addressing hot spots early, the company was able to reduce downtime and increase its production efficiency. Optimising furnace operations with NIR-B cameras based on flame optimisation helped to reduce energy consumption and operating costs. This monitoring also helped the company to ensure consistent product quality and reduce defects. Real-time monitoring of furnace operations with NIR-B cameras helped to identify potential hazards and improve safety in the manufacturing process, allowing operators to quickly identify and address any issues or inefficiencies – reducing maintenance costs and helping to prevent costly repairs.

Additionally, the O-I Seville plant has implemented automation systems to improve production efficiency and reduce the risk of errors. For example, automated inspection systems ensure that only high-quality products are shipped to customers, reducing waste and improving customer satisfaction.

© Technews Publishing (Pty) Ltd | All Rights Reserved