BMG’s Timken Quick-Flex couplings, which require minimal maintenance, are able to withstand extreme applications, including hydraulics, pumps, gearboxes, compressors, vibrator screens, and fans. They are designed to transmit torque from a driving shaft to a driven shaft and to accommodate shaft misalignment within the drive. These maintenance-free couplings also dampen vibration and torque fluctuations, and smooth torsional shock loads.

“An advantage of Quick-Flex drive couplings over conventional units is direct replacement with virtually all comparably-sized couplings. Quick-Flex couplings require no lubrication, and are also easy to install and maintain,” says product manager, Brandon Bouillon. “Due to the high torque capacity of this range, the selected QF solution is often smaller than the replaced coupling. This leads to a major weight saving on the drive and also reduces stress on other components. These couplings are ideal for heavy start-ups of shock loads because they have an impact load capacity in excess of 200% of the maximum torque rating.”

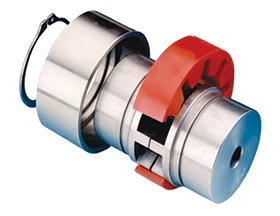

Timken Quick-Flex couplings consist of two steel coupling hubs which are attached to the drive and driven shaft. A urethane element wraps around the two hubs and provides an effective drive mechanism. The only spare part required is a standby element that can be quickly changed when necessary. The cover, which secures the insert in place, can be installed on either side of a standard coupling hub, and will not move under misalignment.

Once the two coupling hubs, insert and cover have been installed and aligned for the first time, the coupling hubs do not need to be moved again for the life of the equipment. Unlike a standard jaw-type or gear coupling, there is no metal-to-metal contact between the hubs. This prevents any possible damage to the ironware during an element failure. The urethane insert can be easily changed without moving the hubs or shafts and no re-alignment of components is necessary.

Inserts, which are resistant to chemicals, are manufactured from different grades of urethane to suit various industries. The red insert is made from relatively soft urethane and is suitable for most high-speed applications with high levels of vibration. This insert is also designed for quick starting and stopping of high inertial loads and for reversing applications.

Quick-Flex couplings, with the stiffer blue insert for higher torque applications, can withstand operation in temperatures between -50 and 100˚C, and are an efficient replacement for gear, disk or grid style couplings.

White inserts are manufactured from a heat-resistant urethane compound for high torque, high temperature applications, up to 177˚C. Couplings with the black insert can withstand extremely high torque requirements, replacing gear style couplings.

Quick-Flex couplings are compatible with shaft sizes from 10 to 286 mm, and can accommodate a wide speed range – from below 100 rpm, to 12 000 rpm. Torque ratings range from 43 to 188 795 Nm, depending on the selected element and cover design.

The flexibility of this design makes these couplings suitable for many applications − from high speed/low torque/excessive vibration drives to a low speed/high torque application. These couplings accept angular misalignment up to 2º and parallel shaft displacement up to 1 mm.

BMG has a team of mobile technicians with specialist technical skills and equipment to conduct breakdown and routine maintenance on site. This team carries out troubleshooting and advises on possible productivity improvements, to ensure the highest level of plant output and reliability.

Specialist services include installation, adjustment, replacement and maintenance of components; shaft and pulley alignment, balancing, condition monitoring, oil sampling and analysis; and critical equipment inspections and lubrication schedules. Maintenance training and fault diagnosis also form an important part of BMG’s field services.

Through BMG’s assistance with careful and accurate product selection, correct installation and appropriate care of couplings, substantial savings can be made in reduced maintenance costs and minimal downtime.

| Tel: | +27 11 620 1500 |

| Email: | [email protected] |

| www: | www.bmgworld.net |

| Articles: | More information and articles about Bearing Man Group t/a BMG |

© Technews Publishing (Pty) Ltd | All Rights Reserved