Voith Turbo is presenting its compact DrivAx IQ4 and DrivAx RQ4 variable speed pump drives at the 2022 Hannover Messe trade fair. The new drives extend the broad portfolio of the DrivAx product family. Other highlights at the drive specialist’s exhibition stand are the self-contained servo drive DrivAx CLDP, whose ten year success story is set to continue with new sizes, and the DrivAx CLCP, which was specially developed for robotics applications.

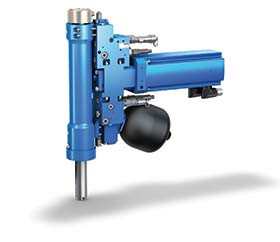

DrivAx IQ4 drives consist of a servo motor and directly mounted internal gear pump that jointly control volumetric flow and pressure. The system allows for a maximum volumetric flow of 125 l/min and a maximum pressure of 270 bar. The speed-controlled pump drive combines energy efficiency with high power density and robustness. Unlike conventional valve-controlled hydraulic systems, the DrivAx IQ4 offers power on demand. Thanks to this power-on-demand principle, the system can operate energy-efficiently at lower speeds in the part-load range and outside the machine cycle. The compact design and interface architecture allow easy integration into machine and control systems.

The DrivAx RQ4 consists of a servo motor and directly mounted radial piston pump that together regulate a volumetric flow of maximum 450 l/min at a maximum pressure of 350 bar. The speed-controlled pump drive combines energy efficiency with high power density and robustness. In addition, unlike conventional valve-controlled hydraulic systems, the DrivAx RQ4 offers power on demand. This means that the system works efficiently at lower speeds in the part-load range and outside the machine cycle. This power-on-demand principle, in combination with the load-dependent switchable pump, allows special load profiles with reduced size motor and peripherals to be realised. The compact design and interface architecture allow easy integration into machine and control systems.

Ten years ago, Voith ushered in the revolution in self-contained servo drives with the introduction of the DrivAx CLDP. Currently, more than 1000 servo drives are in operation worldwide. To coincide with this anniversary, the technology group is presenting two new sizes for the self-contained servo drive product line at Hannover Messe 2022. Users therefore now have five sizes to choose from, which allows even more precise adaptation of the servo drive to the respective application.

The main components of the CLDP linear servo drive are a servo motor, an internal gear pump and an actuator. Pressure and/or position sensors ensure the precise control of force and position, while the speed and directional control of movement are effected without valve technology. Thanks to this design principle, there is no need for a hydraulic unit or piping. The compact design and interface architecture allow easy integration into machine and control systems. The DrivAx CLDP also offers an alternative to electromechanical drives. The technology combines the robustness and power density of hydraulics with the controllability of servo technology. Other benefits are the almost wear-free operation, resistance to force peaks, lower energy requirement and the elimination of cooling and lubricating units.

The DrivAx CLCP servo drive is a self-contained linear drive with an outstanding power-to-weight ratio. This also makes the linear drive an ideal alternative for robot-assisted applications. The main components of the DrivAx CLCP are a servo motor, a 4Q internal gear pump and an actuator. Pressure and/or position sensors ensure the precise control of force and position, while the speed and directional control of movement are effected without valve technology. This design principle means that there is no need for a hydraulic unit or piping. The load-adaptive or electro-hydraulic gear shifting reduces the size of the components and thus lowers procurement and installation costs. The compact design and interface architectures allow easy integration into machine and control systems.

Thanks to these characteristics, the self-contained DrivAx CLCP linear drive also offers an alternative to electromechanical drives, as the technology combines the robustness and power density of hydraulics with the controllability of servo technology. Other benefits are the almost wear-free operation, resistance to force peaks, lower energy requirement and the elimination of cooling and lubricating units.

© Technews Publishing (Pty) Ltd | All Rights Reserved