Efficient spillage solutions

January 2023

Motion Control & Drives

OST-Africa’s range of materials handling, screen and transmission products includes an efficient spillage solution, designed to prevent production losses during materials handling in diverse sectors.

“This cost-efficient spillage system, which encompasses various products that operate together to form one highly efficient system, has important benefits over conventional systems which are labour intensive, costly to operate and require additional equipment,” says Nolene Streicher, managing director of OST-Africa, which is part of the Engineering Solutions Group (ESG) of Invicta Holdings. “Advantages of the OST system include simple installation, modular components for extended service life of the system, reduced maintenance and a low cost solution to spillage problems.”

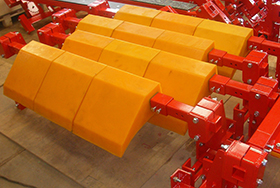

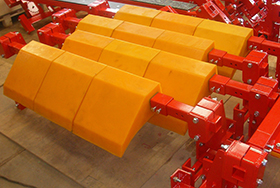

The OST spillage system consists of a dynamic impact bed, the high impact torsion (HIT) system, the skirt clamp and skirt wing, impact zone panels, chute vibrators, duff feeders, primary and secondary belt scrapers and the bias plough.

The dynamic impact bed is a shock absorbing trough, which is mounted underneath a conveyor belt. It is installed at transfer points where fine or coarse heavy material is being transferred and where there is a build-up of materials in the transfer chute. The HIT system combines a heavy-duty idler frame with a high-impact torsion arm system to absorb the impact of material which falls onto the belt.

The skirt clamp, which is the conveyor system’s spillage controller, ensures that positive pressure is always applied to the side wall. The skirt wing is designed to support a conveyor belt between the idler and frames when sagging occurs, in order to prevent overflow spillage.

OST impact zone panels are used at high-impact points in transfer chutes which are continually put under high stress and therefore have the highest maintenance requirements. This impact zone panel absorbs impacts and high-wear-resistant liners ensure efficient operation and extended service life.

Chute vibrators prevent material blockage in a chute. Duff feeders, which accommodate the removal of dry or wet material from underneath belt scrapers down to collection points, also allow access for easy maintenance of conveyor rollers and belt scrapers.

The primary belt scraper blade tip is kept in positive contact with the belt surface while the secondary belt scraper is segmented from all scraper components for extended service life. The bias plough prevents duff that remains on the belt from damaging the return pulley.

OST’s materials handling product portfolio also includes the Grizzley Feeder System (GFS), which is custom made to suit each application. This mobile feeder system, which constantly controls the feed of product onto conveyor belts at a rate of up to 80 tons per hour, can be quickly and easily dismantled and relocated when necessary. This system, which ensures optimum production, reduced wear and low maintenance, is also designed for no spillage.

Electrical panels for these feeders are fitted with manual and automatic switches, frequency inverters, overload switches, flexible vibration cables and a step-down transformer. OST bulk handling systems are supported by OST-Africa’s specialised design and installation team, which ensures these custom-built systems meet exact requirements in any application.

For further information contact Chantelle Roelofse, OST-Africa, +27 12 803 7262, [email protected], https://ost-africa.co.za

Further reading:

Novel bearing steel next generation of aeroengines

SKF South Africa

Motion Control & Drives

SKF continues to re-imagine intelligent and clean rotation with the development of an innovative temperature-resistant, corrosion-tolerant steel called ARCTIC15 designed for aeroengine bearings.

Read more...

Products from maxon

Motion Control & Drives

A wide range of new products is available from motion control specialist, maxon. with a diverse technology portfolio ranging from highly integrated robotic actuators to powerful servo drives and controllers.

Read more...

Actuators for precise hexapod movements

Motion Control & Drives

Aerotech, manufacturer of high-performance motion control and automation systems, is expanding its Automation1 platform. These compact hexapod devices enable the complete integration of six-axis motion systems into existing control

Read more...

Strategic system upgrades beat mining obsolescence and drive productivity

Motion Control & Drives

Mining operations are under constant pressure to maintain output while controlling costs. One persistent challenge continues to confront the industry, knowing when and how to upgrade aging systems before they become a liability.

Read more...

Precision meets performance: The ELGD Axes Family from Festo

Festo South Africa

Motion Control & Drives

Festo has introduced the ELGD axes family, engineered for the demands of future-focused industries. With cutting-edge guide technology, exceptional rigidity and high load capacity, these axes deliver more performance within the same installation footprint.

Read more...

Condition monitoring in hazardous areas

SKF South Africa

Motion Control & Drives

SKF is further strengthening its condition monitoring offer portfolio by a newly developed hazardous area version of its Microlog Analyzer dBX portable vibration analyser.

Read more...

Rip-and-ship solution speeds up nuclear decommissioning project

Motion Control & Drives

When removing steam generators from decommissioned nuclear reactor buildings, the most economical method is to remove them in one piece. Mammoet was commissioned by Framatome to support with the removal of four steam generators from PreussenElektra’s Nuclear Power Plant Unterweser in Germany.

Read more...

WearCheck turns the focus on friction modifiers

Wearcheck

Motion Control & Drives

One of the most important features of a lubricant is the reduction of friction between two surfaces.A dditives like friction modifiers are added to perform this function. Wearcheck turns the focus on friction modifiers

Read more...

SEW-EURODRIVE transforms drivetrain uptime

SEW-EURODRIVE

Editor's Choice Motion Control & Drives

The DriveRadar IoT Suite from SEW-Eurodrive is an ideal solution for industrial condition monitoring. This powerful ecosystem of intelligent sensors, edge devices and cloud-based analytics ensures that customers have full visibility and control of their operations.

Read more...

PC-based control for flat wire motors for electric vehicles

Beckhoff Automation

Editor's Choice Motion Control & Drives

Special machine manufacturer, ruhlamat Huarui Automation Technologies has unveiled the second generation of its mass production line for flexible stators with bar winding (pins). This enables an extremely short production cycle and line changeover times, supported by PC- and EtherCAT-based control technology from Beckhoff.

Read more...