Automated weld seam tracking in robot welding cells is a complex task in a harsh industrial environment. The micrometre-accurate detection of the guide point with different types of joint by 2D/3D profile is one of the most effective solutions for this challenge.

In combination with Wenglor’s uniVision software, the new weCat3D MLZL 2D/3D profile sensor not only combines the necessary precision and profile quality (1280 points per profile), but also offers convenient installation, integration, robustness and user-friendliness. The working range is from 74 to 158 mm and the measuring range on the X axis is 39 to 62 mm.

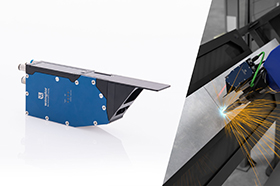

The slimline housing of the MLZL – with integrated cooling and rinsing – enables easy, space-saving installation directly on the welding torch. With dimensions of only 33 x 183 x 69,8 mm, the robot can also operate in narrow corners. The sensor does not require any additional protection housing thanks to its IP67 rating, nor does it need to be tilted for alignment. The design also offers sufficient protection against welding splatter and disturbing ambient light.

Optionally equipped with a red or blue laser, users can choose between three laser classes: 2M, 3R or 3B. The MLZL relies on the advanced laser technology of the weCat3D series from Wenglor to deliver optimal profile quality and seam tracking.

uniVision 2.5.0 for welding applications

The standard configuration software uniVision now incorporates a standalone module specifically for weld seam tracking, helping to get welding applications set up in just a few clicks. Due to the robust algorithms, tracking points can be determined reliably even in the event of faults in the joint course, such as with datum points. Predefined templates, where all common joint types are saved, significantly reduce the configuration work. The result can be visualised in a web browser, with several interfaces available for direct integration into robot controls from Kuka, Fanuc, ABB, Kawasaki and Yaskawa.

uniVision software is used to analyse images and height profiles in the field of industrial image processing. Two- and three-dimensional data from smart cameras, vision systems, smart 2D/3D profile sensors and industrial PCs with 2D/3D profile sensors can also be evaluated. In total, up to 25 different software modules and various templates are available to users, depending on the selected hardware.

The new combination of software and hardware offers flexible solutions for every user. The most convenient and comprehensive system consists of a sensor, control unit with pre-installed uniVision software application, and optional robot interface. There are also other combinations, with or without a control unit and/or customer-specific integration software, which translates to Wenglor being able to offer the right solution to suit every individual requirement.

© Technews Publishing (Pty) Ltd | All Rights Reserved