Temperature measurement has never been easy because of the physics involved. Temperature sensors are complex and there are many types to choose from, based on the particular physical properties behind the way they represent temperature. It is common knowledge that temperatures range from absolute zero (i.e., 0 Kelvin, which equates to -273,15°C) through to molten metal which can be thousands of degrees Celsius, so there is no such thing as a one-size-fits-all temperature sensor.

Temperature sensors are chosen for their suitability to the temperature range they need to measure, with accuracy, linearity, stability and repeatability being key performance criteria. Technical specialists are required to set up, calibrate and validate the measurement.

Omniflex has invested many years of research and development into temperature signal conditioning for the industrial environment, where control and measurement of temperature is key to many processes. Temperature monitoring for storage is a key performance metric in many commercial retail and pharmaceutical operations as well.

It is important to remember that the temperature sensor is only measuring temperature at its own position in the room, fridge or freezer, so it stands to reason that the more temperature points you monitor, the better, in order to get a clear representation of the temperature in the space you are monitoring.

The downside is the expense of temperature sensors, so there is inevitably a trade-off between that and the cost benefit of having many sensors for a given storage space. But with regulatory controls and financial liability now forcing auditable record-keeping that cannot be manipulated in the process, a temperature monitoring system needs to be cost effective, reliable and meet regulatory standards.

A good example is the FDA (Food and Drug Administration of USA) 21 CFR Part 11 for pharmaceutical and research environments, which states that “Any studies in which data will be submitted to the FDA, regardless of drug or device status, must also comply with the 21 CFR Part 11 requirements. In addition, some funding agencies or the study grant may require that study records be kept in a 21 CFR Part 11-compliant system.” However, even the food and beverage industry vendors are obliged to show compliance in cold chain management to the public, regulatory bodies and their insurers.

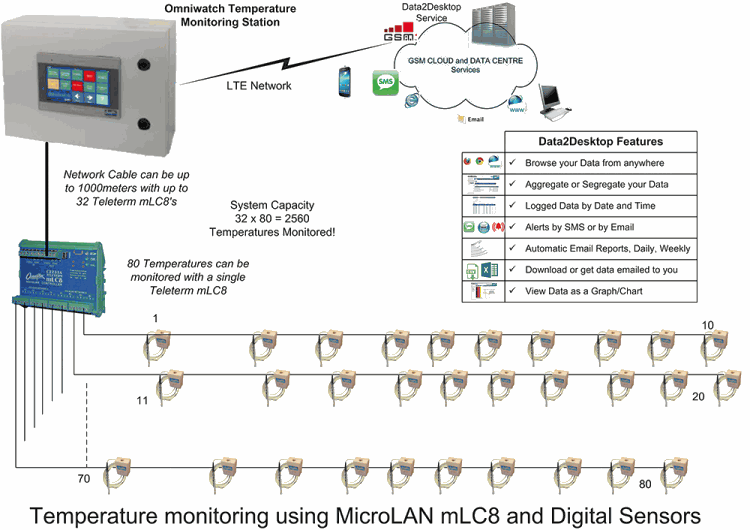

Omniflex has developed a cost-effective solution for applications that need larger temperature coverage, easy onsite configuration and a simple connection system that does not require expensive expertise to apply and maintain. This solution provides a front-end device – the Teleterm mLC8 – which supports up to 80 digital temperature sensors using the Omniflex microLAN network.

Up to 10 plug-in temperature sensors can share a two-wire cable on the mLC8, which has eight ports, enabling 80 temperature sensors to be monitored. Up to 32 mLC8s are supported by the touchscreen HMI, so a system with 2560 temperature points can conceivably be constructed. The system is reliable and dependable, safe and secure, simple to replace and maintain, and comes with a single central management terminal for surveillance of the entire system. Cloud-based historical logging and storage options are also available.

The touchscreen HMIs range from 5 to 15-inch display sizes to suit various application types and space constraints, and they provide the management oversight required to manage the facility. The cloud-based history provides the compliance records needed for the facility.

BYOGD – Bring Your Own Giant Display

An additional option is to use the EasyView FHD module technology with Full HD (1080p) capability and HDMI interface. This opens up the potential for giant screens that can visually service an entire control room, using large wall-mounted computer display panels or TV screens – no PCs required. In this way, a full temperature monitoring overview can be displayed front and centre, keeping all plant personnel focused at all times, with immediate alerts for over-temperature alarm conditions.

Applications for this solution include pharmaceuticals, laboratories, supermarket fridges and freezers, logistics warehousing, abattoirs, building management and air conditioning, cold rooms, computer server rooms and server farms.

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved