No matter how the world changes, or which future technologies and developments will be relevant tomorrow, all of it is already anticipated today in the Totally Integrated Automation (TIA) offering from Siemens, integrated step-by-step to add real added value for customers in both the discrete and process industries.

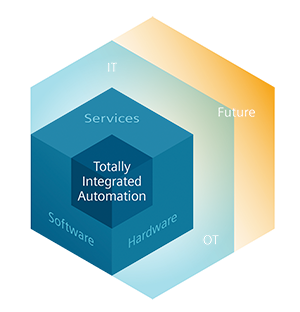

TIA brings together what belongs together – hardware, software, services, IT, and OT – and keeps on growing steadily through the integration of new technologies. Discover everything that’s in TIA, the leading automation concept from Siemens and how it all works together to create a unique product for machine builders and industrial enterprises. It is an open system architecture and has been enabling the seamless interaction of all automation components, the software involved and higher-level systems and services, since 1996. This is ensured by consistent data management, global standards and uniform interfaces – from the field to corporate management level.

End-to-end consistency, while not a result in itself, reduces expenditure, saves time and enables a step into the next dimension on the path to the digital enterprise, always allowing room for future innovation and growth.

Added value in three dimensions

TIA stands for complete integration. Hardware, software and services merge seamlessly and information flows both horizontally and vertically. New technologies are integrated in TIA one step at a time. The result is real added value across all industries – regardless of the type of automation or to what degree of digitalisation the company has progressed.

TIA connects what belongs together, and thus enables the implementation of the digital enterprise. Ongoing integration of new technologies makes the automation portfolio future-proof. This world-leading automation concept stands for absolute end-to-end consistency in three dimensions.

Integration¹ – integration of hardware, software and services

With all software and hardware components working together smoothly, TIA provides maximum consistency and transparency. The combination of a comprehensive engineering approach, integrated security and safety technologies, communication standards and data intelligence delivers real added value across the entire value chain. Specific services, from consulting to implementation and optimisation, help machine builders and plant operators uncover hidden potential and fully exploit it.

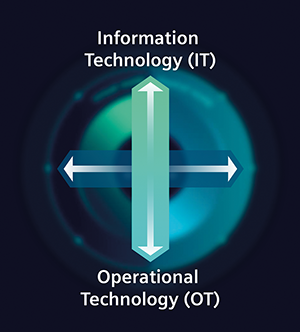

Integration² – horizontal and vertical integration

Comprehensive data use is made possible by merging the virtual and physical worlds. This is where TIA comes in: seamless end-to-end connectivity enables field and machine levels to be linked together horizontally and OT and IT vertically. The open nature of TIA allows existing software and applications to be ported to the Edge Management System without difficulty, for example. Users also benefit from integrated security and connectivity between their automated system and the cloud. The range of TIA services is rounded out by scalable solution packages, the TIA Use Cases, which help implement the digital enterprise and illustrate how the challenges of the future can be overcome quickly and without complications.

Integration³ – the future of the digital enterprise

Given the industrial sector’s high CO2 emissions, it is especially important for manufacturing companies to think about how they can reduce their carbon emissions in the coming years. However, we cannot do this alone! Let’s join forces to shape a sustainable future together.

Benefit from existing expert knowledge, applications and examples. Attend one of our information sessions or view recordings and presentations from past events.

From OT to IT with TIA

To make even more comprehensive use of data and draw robust insights from it, users need high-performance data throughput and seamless data processing all the way from the shop floor to the top floor. The TIA concept has an especially important role to play in this regard.

By merging the virtual and physical worlds, the convergence of Operational Technology (OT) and Information Technology (IT) is being driven forward. The goal is to structure production processes as flexibly, intelligently and autonomously as possible to master the challenges of tomorrow.

The strengths of the TIA Portfolio come into play at the transition between the virtual and physical worlds, with opportunities to simulate controllers and perform virtual commissioning and generate, communicate and analyse production data on an ongoing basis.

Comprehensive, consistent and unique

With a comprehensive approach to engineering and integrated security and safety technologies, plus communication standards and data intelligence, the result is true added value along the entire chain.

TIA enables comprehensive engineering, from mechanical design to electrical layout and automation, which reduces costs as well as time and effort. The TIA Portal makes available a standardised engineering tool for the entire automation process and simplifies and speeds up engineering activities. NX Mechatronics Concept Designer is an end-to-end solution for building machines across disciplines faster and with the highest quality. The necessary consistent data management is enabled by Teamcenter, a Product Lifecycle Management (PLM) system, which combines all the steps in the value chain.

Step by step to the autonomous factory

Data-driven process optimisation is becoming increasingly important for machine builders and plant operators. Due to the increasing use of intelligent system components that can produce their own data, the requirement to make use of this information to derive improvement from it is also increasing.

The use of artificial intelligence makes the handling and processing of this data significantly easier, faster and more precise. However, implementing artificial intelligence takes time. In addition to creating and validating an AI model, another major challenge is its reliable and stable implementation in the plant process. TIA significantly facilitates this task as well.

Discover the potential of new technologies like AI in a dynamic industrial environment and an increasingly resource-sensitive, while at the same time, individualised world. Learn what is already possible today and where the journey is heading. What needs to be considered and how important it is to explore, experiment and move forward together.

The TIA portfolio from Siemens is constantly expanding to include more innovative technologies. For example, artificial intelligence, autonomous systems, blockchain, cognitive engineering and

5G will strongly define the future of automation. To ensure seamless integration, Siemens is already incorporating all of these in its thinking for TIA and integrating them step by step. This benefits companies by helping them to remain future-proof and prepared to meet existing and future challenges.

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved