In the oil and gas refining industry, catalytic hydro processing units such as hydrotreaters (HDT), hydrodesulfurisation (HDS) and hydrocracker units (HCU) rely on high-performance catalyst technologies to maximise product conversion while efficient reaction control seeks to keep the environmental footprint and cost down. Precise and reliable temperature mapping of densely packed reactor catalyst beds therefore makes an essential contribution to stable and profitable unit operations.

Multipoint temperature instruments with thermocouple sensors are widely used in the industry as they monitor optimum heat distribution, preventing hotspots and premature catalyst deactivation under high-temperature, high-pressure and corrosive conditions.

However, most conventional multipoint thermocouple probe designs have two major weaknesses:

• Reliability – a phenomenon known as hydrogen sulphide (H2S) contamination affects conventional magnesium oxide (MgO) cables under extreme process conditions. H2S contamination can alter measurement accuracy or even lead to a loss of control over the reaction with potentially disastrous consequences.

• Size – they are comparatively invasive, taking up valuable space in catalyst beds, leading to undesired pressure drops and channelling effects. Their mechanical footprint is a trade-off against denser catalyst loads.

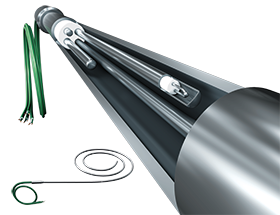

A new, robust multipoint thermocouple probe design addresses these issues by combining thermowell and thermocouple sensors in a single space-saving probe, addressing failure vulnerabilities while providing more efficient catalytic reaction. The patented technology helps the automation system provide more reliable, precise and accurate process control, directly contributing to improved safety, profitability and uptime.

Thermocouple drift and migration

The harsh environments typically encountered in catalytic hydrocracker units pose a difficult challenge for process instrumentation. While all thermocouple probes are known to drift over time, mechanical stress, abrasion and H2S contamination are often not factored in when specifying design limits and making instrument vendor selections. Unfortunately, these issues can lead to a total loss of data, threatening process safety, reaction control and efficiency.

In these particular applications, industry expectations of a multipoint temperature instrument’s usable life (wetted parts) are typically one or two-unit operation cycles or turnarounds (i.e. between 36 and 84 months). Standard thermocouple sensors are embedded in insulating magnesium oxide (MgO) powder, providing some level of protection. However, under extreme conditions, even microscopic cracks forming in the outer sheath allow hydrogen sulphide to permeate into the MgO powder, causing detrimental contamination of the internals.

Defective thermocouple probes have been found in a significant number of applications throughout the industry. This occurrence has subsequently been examined scientifically, resulting in the discovery of two phenomena that degrade thermocouple measurement performance: thermocouple drift and hot junction migration. These effects can occur separately or in combination.

Thermocouple drift: chemical contamination of the MgO powder induces a change in the composition of the two dissimilar metals that make up the thermocouple conductor wires, leading to a shift in potential difference due to the Seebeck or thermoelectric effect. While the local hot junction remains intact, a change in conductivity of one or both metals will alter the measured voltage and thus negatively impact measurement accuracy.

Hot junction migration: permeation of H2S into the MgO powder can cause new conductive bonds (electrical short circuits) to form between the thermocouple wires at undesired locations away from the hot junction. The thermocouple will still work but will present incorrect values.

If one or several defective thermocouple sensors have been identified, process owners might decide to address the issue during the next scheduled unit turnaround. Depending on the severity of the failures and their safety criticality, it might also be warranted to initiate extraordinary maintenance for sensor replacement. While this option may be the safest choice, it also entails an unscheduled unit shutdown, a complex and costly operation.

Solution

A new, robust multipoint thermocouple probe design combines thermowell and thermocouple sensors in a single space-saving probe, addressing failure vulnerabilities with immediate benefits toward a more efficient catalytic reaction. The patented technology delivers more reliable, precise, and accurate process control, directly contributing to higher safety and profitability in hydro processing operations.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved