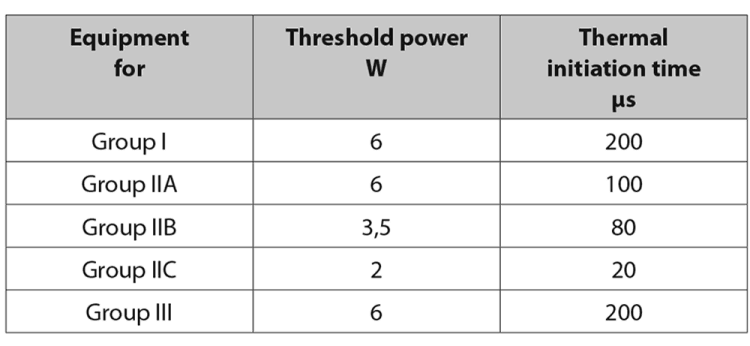

From the standards: Radio Frequency Sources (9 kHz to 60 GHz) for continuous transmissions and pulsed transmissions, whose pulse duration exceed the thermal initiation time, shall not exceed limits below:

State of legislation

For Group I in South Africa, there were DMR directives (ME-2-2003 signed; MS-2-2010 unsigned) that contradict the IEC/SANS60079-0 standard of 6 W RF transmission, stipulating 500 mW.

I do not believe there is a mechanism to remove or update these directives? What happens if the requirements become outdated? Would it be worth including any DMR directives in the next version or release of the ARP?

The Mine, Health and Safety Act still specifically refers to ARP0108:2005. There have been several new releases of this document, with several new requirements inserted for mining. So how do these new requirements in later versions of the ARP stand in law?

Is the 500 mW limit in underground coal mines a limiting factor? What is the risk?

History: the 500 mW limit dates back over 20 years and a lot has changed in this time. MS-2-2010 details concerns over spurious triggering of detonators and interference with electronic safety related equipment. It also states that testing to EMC standards SANS61000 (CE marking) will improve RF susceptibility.

Common sense though would suggest not putting the access points (Aps) anywhere near the detonators anyway. In addition, RF fields drop away very quickly as you move away, so even at 1 m, the RF field has reduced significantly. It does depend on the type of antenna (directional, omni-directional etc. and gain), but as an example using gain of 1:

Power received = Power transmitted/4 π x distance^2. So at 1 m away from 100 mW AP, the power is 8 mW.

Section 3 of MS-2-2010 states the use of effective radiated power (ERP). This directive sets the maximum ERP for any wireless communication system in mines at 500 mW. Where mines are already using, or planning to use, wireless communication systems that exceed 500 mW ERP, a risk assessment should be performed to determine control measures that may be required in the use of that communication system in the proximity of any critical and safety-critical systems.

So, the 500 mW is not an absolute limit: a risk assessment should be done prior to use.

In conclusion: I do not really believe the 500 mW is an issue anyway. Typically, Wi-Fi APs transmit at 100 mW, so provided sensible gain antennae are used, there is no concern with respect to the 500 mW limit. (See comments below on using LTE with mobile devices.)

Rewards and benefits associated with the use of Wi-Fi

Underground use of Wi-Fi offers significant safety and operational improvements:

• Real-time location tracking systems (RTLS): with the use of intrinsically safe (IS) Wi-Fi tags, everyone underground can be tracked for location. In the event of mustering or evacuation, the location of everyone is known and help can be sent to those that need it.

• Geo-locations can be set up to prevent machines operating if there are unauthorised people present.

• Tags and mobile devices offer Man Down and Lone Worker functionality.

• Communications via IS mobile devices (e.g. smartphones, tablets).

• Access to documentation.

• Training can be facilitated.

• Remote eyes and virtual support: underground workers can be supported technically by an expert, thousands of km away, without the need for travel, security, etc. to get to the root of the problem.

• Data extraction can be used for operational analysis and optimisation.

Cellphones and SIM cards: Is there a risk if a SIM card is fitted to a mobile device?

Mobile devices typically transmit at less than 2 W for GSM/3G/LTE and less than 100 mW for Wi-Fi.

So, mobile devices could theoretically exceed the 500 mW limit using GSM/3G/LTE, but they require communication with a tower and there is not one present in an underground mine!

It is highly unlikely that a mobile device will transmit without receiving a synchronisation signal from a cell tower. If a device is connected to a network and you do go underground, the device will increase its power output trying to reach the tower it was connected to. But once that link is broken, it will not transmit until a sync signal is received.

Note though, that if LTE is considered underground, the fact that mobile devices are likely to transmit over 500 mW should be considered.

In conclusion, there is more risk by modifying the devices to prevent SIM cards being fitted (and invalidating the certification and warranty by tampering with an IS device) than the risk of LTE at 2 W.

In the author’s opinion, Wi-Fi and all it offers can dramatically improve safety in all industries, including underground coal mines. In fact, the risk of not using Wi-Fi is a far bigger issue.

There would be significant advantage in having legislation that clearly lays out what is allowed and what is considered safe.

| Tel: | +27 10 055 7300/1 |

| Email: | [email protected] |

| www: | www.extech.co.za |

| Articles: | More information and articles about Extech Safety Systems |

© Technews Publishing (Pty) Ltd | All Rights Reserved