New resources, compounds and all sorts of active ingredients are continuously being developed to meet the ever-growing demand of all industries and for various uses in everyday life. Using the best-available technologies is standard practice for chemical reactors, distillation, precipitation, drying, milling, granulation and other associated processes.

The specifications for control in chemical and pharmaceutical production processes are rigid, meaning only products approved for harsh environments can be used. No wonder the demand for Danfoss expertise and quality products has continued through the years and even during the worldwide pandemic. Danfoss Drives Chemicals has constantly ensured high levels of reliability and safety, long service life and high levels of performance and energy efficiency.

Efficient supply, refining and transportation of raw materials stored at specified temperature levels can always be achieved with refrigeration solutions from Danfoss. And when it comes to the best-available technology for AC motors, the industry recognises the benefits of speed control using AC drives.

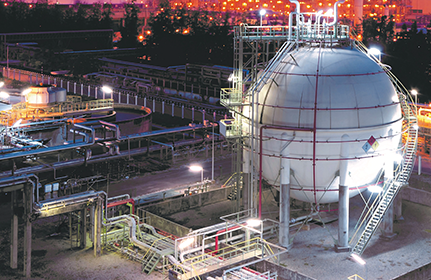

Danfoss offers its widespread experience and expertise in refrigeration and in controlling the speed of AC motors in all the main chemical sectors: petrochemicals, basic inorganics, polymers, specialty and consumer. The range of refrigeration equipment and AC drives is designed to fulfil the demands of the chemical industry where safety has the highest priority.

Quality chemical plants powered by quality drives

Process-control improvements with speed control of motors and proven energy savings in various applications have increased the output and reliability of plants and reduced carbon emissions.

For chemical plants to run at their absolute best, drives are required that enable peak performance. Designed with decades of industry expertise, Danfoss quality AC drives deliver best-in-class reliability and robustness. Their leading energy efficiency lowers total cost of ownership and makes a positive contribution to reaching the world’s climate goals. Further, predictive and condition-based monitoring is built in to give users the intelligence they need to future-proof their systems. The Danfoss drives product line is fully compatible with any motor or system, which leaves users free to run the optimal system for their plants.

Energy efficiency

Danfoss AC drives are highly energy efficient, helping increase plant ROI and reduce TCO. They have excellent back-channel cooling, reducing the need for air conditioning, as well as smart tools that lower energy use and application wear. Higher power density also eliminates the need to use oversized drives, while at the same time lowering energy consumption.

AEL Intelligent Blasting cuts energy consumption by 500 kWh per hour

This 720 mtpd nitric acid plant in South Africa saves R3,6 million annually on operating costs, thanks to an upgrade from direct-on-line operation to Danfoss VLT drive control of electric pumps and motors.

For many years, motors and pumps in the process cooling water system operated direct-on-line. With the upgrade, AEL Intelligent Blasting aimed to improve efficiency and reliability by introducing AC drive motor control. It chose VLT AQUA Drive FC 202 and VLT HVAC Drive FC 102 drives from Danfoss, based on their ability to ensure stable operation despite unreliable mains power supply. These drives offer automatic energy optimisation and kinetic back-up features to support highly efficient and reliable plant operation.

The remarkable payback time of only 18 months reflects the vast improvement in process cooling water efficiency enjoyed by AEL Intelligent Blasting. “The drives were selected based on the kinetic back-up feature, which is valuable to us because of our unstable electricity supply and a number of small voltage dips that cause our facilities to trip,” concludes Johan Engelbrecht, AEL Nitrates MV electrical engineer. “With this feature we can keep the plant online without any issues, therefore saving millions.”

© Technews Publishing (Pty) Ltd | All Rights Reserved