Belt tracker eliminates conveyor problems

February 2021

Maintenance, Test & Measurement, Calibration

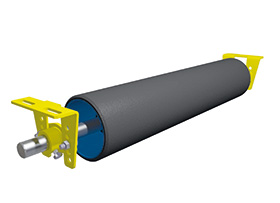

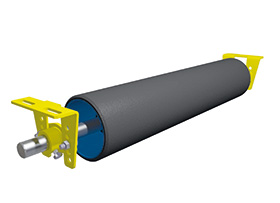

BLT World’s comprehensive range of bulk materials handling equipment encompasses conveyor components, designed to enhance productivity, minimise downtime and ensure extended service life of conveyor systems. New to this range is the Scrapetec PrimeTracker belt tracking system, which eliminates problems associated with belt conveyors, including misalignment, abrasion and belt damage.

“For optimum performance of a conveyor system, it is critical that the belt always runs straight on the conveyor, without sideways movement,” explains Ken Mouritzen, managing director, BLT World. “Our new PrimeTracker belt tracker has been designed to guide a conveyor belt back into the correct straight-line position, to prevent costly downtime and component replacement. An advantage is that it operates in the idling position at all times, unless there is sideways movement of the belt. This system corrects misalignment immediately, by guiding the belt back into the correct position, with no damage or abrasion to the belt or tracker.

“This is unlike conventional belt trackers that slide over the belt surface, causing possible abrasion and belt damage, rather than adopting free rotation. Conventional belt trackers, with tapered edges, never idle and are always in a braking mode.

“What is also notable is the cylindrical shape and pivot bush that allow this belt tracker to swing and tilt during operation and to always be in full contact with the belt. Added to this, the Scrapetec PrimeTracker has the same peripheral speed over the entire surface of the belt, where traditional crowned rollers have different speeds at the centre and edges of the system.”

Other advantages include easy installation, low maintenance requirements, and protection of belt edges and the structure of the conveyor belt. A strong corrugated rubber hose protects this system from dust and sand, while the rubber pivot offers soft suspension of the tracker shaft, extending the service life. This system can be installed in front of every return pulley, above and below the belt.

BLT World also supplies and supports Scrapetec products for conveyor systems, which are designed to prevent dust formation, reduce material spill, enable thorough-belt cleaning and minimise the risk of explosion.

Further reading:

OEM-standard repairs for industrial gear units

Maintenance, Test & Measurement, Calibration

BMG, the official OEM for Hansen gearboxes, is authorised to repair Hansen industrial gear units in strict accordance with the manufacturer’s documented procedures, preserving the design tolerances and operational reliability required in demanding industrial environments.

Read more...

The smart choice for test and measurement solutions

RS South Africa

Maintenance, Test & Measurement, Calibration

As the demand for precision and efficiency continues to grow across industries, RS PRO, the own brand of RS, provides a complete portfolio of test and measurement equipment engineered to meet the highest standards of performance, safety and value.

Read more...

New frequency counter with 10 digits of resolution

Comtest

Maintenance, Test & Measurement, Calibration

B&K Precisio has a new series of universal frequency counters designed for a wide range of frequency measurement applications.

Read more...

Verification using Heartbeat Technology is a breeze

Maintenance, Test & Measurement, Calibration

Heartbeat Technology reflects Endress+Hauser’s long-term commitment to enhancing measurement reliability and efficiency across a growing product portfolio.

Read more...

Clog-resistant nozzle for powerful stationary tank cleaning

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Clog-resistant nozzle for powerful

Maintenance, Test & Measurement, Calibration

As EXAIR and BETE continue to build on a strong partnership, EXAIR has recently added a selection of BETE products to the site, including the innovative BETE HydroClaw tank and vessel cleaning nozzle.

Read more...

Why your next oscilloscope should

Comtest

Maintenance, Test & Measurement, Calibration

The PC-based USB oscilloscope is a cutting-edge, adaptable alternative to traditional benchtop oscilloscopes that’s redefining test and measurement.

Read more...

Automated test and measurement

Comtest

Maintenance, Test & Measurement, Calibration

Comtest, in partnership with global brands, provides customised solutions with integrated hardware and software for efficient testing and data collection.

Read more...

Advanced field calibrator and communicator

Maintenance, Test & Measurement, Calibration

The Beamex MC6 is a high-accuracy field calibrator that offers automatic calibration capabilities for pressure, temperature and various electrical signals.

Read more...

Inline particle measurement

Mecosa

Maintenance, Test & Measurement, Calibration

Part of the SOPAT family, Parsum has for more than 20 years stood for the measurement of particles in a running process - without sampling and without a laboratory.

Read more...